Page 430 - DC_SWISS(Catalogue_TM_ES-EN)

P. 430

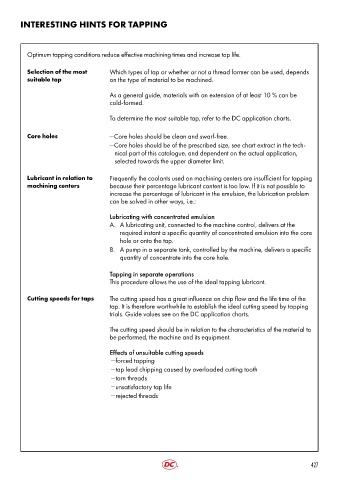

INTERESTING HINTS FOR TAPPING

Optimum tapping conditions reduce effective machining times and increase tap life.

Selection of the most Which types of tap or whether or not a thread former can be used, depends

suitable tap on the type of material to be machined.

As a general guide, materials with an extension of at least 10 % can be

cold-formed.

To determine the most suitable tap, refer to the DC application charts.

Core holes Core holes should be clean and swarf-free.

Core holes should be of the prescribed size, see chart extract in the tech-

nical part of this catalogue, and dependent on the actual application,

selected towards the upper diameter limit.

Lubricant in relation to Frequently the coolants used on machining centers are insufficient for tapping

machining centers because their percentage lubricant content is too low. If it is not possible to

increase the percentage of lubricant in the emulsion, the lubrication problem

can be solved in other ways, i.e.:

Lubricating with concentrated emulsion

A. A lubricating unit, connected to the machine control, delivers at the

required instant a specific quantity of concentrated emulsion into the core

hole or onto the tap.

B. A pump in a separate tank, controlled by the machine, delivers a specific

quantity of concentrate into the core hole.

Tapping in separate operations

This procedure allows the use of the ideal tapping lubricant.

Cutting speeds for taps The cutting speed has a great influence on chip flow and the life time of the

tap. It is therefore worthwhile to establish the ideal cutting speed by tapping

trials. Guide values see on the DC application charts.

The cutting speed should be in relation to the characteristics of the material to

be performed, the machine and its equipment.

Effects of unsuitable cutting speeds

forced tapping

tap lead chipping caused by overloaded cutting tooth

torn threads

unsatisfactory tap life

rejected threads

427