Page 162 - 21-036 APPLITEC catalogue.indb

P. 162

a e

n

v f

a p

d 1

v c

f z

Q

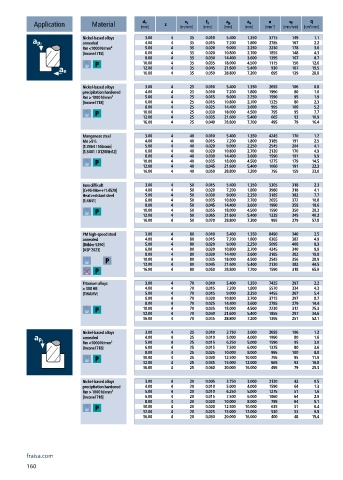

Application Material [mm] z [m/min] [mm] [mm] [mm] [min ] -1 [mm/min] [cm /min]

3

Nickel-based alloys 3.00 4 35 0.010 5.400 1.350 3715 149 1.1

annealed 4.00 4 35 0.015 7.200 1.800 2785 167 2.2

Rm <1000 N/mm² 5.00 4 35 0.020 9.000 2.250 2230 178 3.6

[Inconel 718] 6.00 4 35 0.020 10.800 2.700 1855 148 4.3

8.00 4 35 0.030 14.400 3.600 1395 167 8.7

10.00 4 35 0.035 18.000 4.500 1115 156 12.6

12.00 4 35 0.045 21.600 5.400 930 167 19.5

16.00 4 35 0.050 28.800 7.200 695 139 28.8

Nickel-based alloys 3.00 4 25 0.010 5.400 1.350 2655 106 0.8

precipitation hardened 4.00 4 25 0.010 7.200 1.800 1990 80 1.0

Rm > 1000 N/mm² 5.00 4 25 0.015 9.000 2.250 1590 95 1.9

[Inconel 718] 6.00 4 25 0.015 10.800 2.700 1325 80 2.3

8.00 4 25 0.025 14.400 3.600 995 100 5.2

10.00 4 25 0.030 18.000 4.500 795 95 7.7

12.00 4 25 0.035 21.600 5.400 665 93 10.9

16.00 4 25 0.040 28.800 7.200 495 79 16.4

Manganese steel 3.00 4 40 0.010 5.400 1.350 4245 170 1.2

Mn >5% 4.00 4 40 0.015 7.200 1.800 3185 191 2.5

[1.3964 / Nitronic] 5.00 4 40 0.020 9.000 2.250 2545 204 4.1

[1.3401 / X120Mn12] 6.00 4 40 0.020 10.800 2.700 2120 170 4.9

8.00 4 40 0.030 14.400 3.600 1590 191 9.9

10.00 4 40 0.035 18.000 4.500 1275 179 14.5

12.00 4 40 0.045 21.600 5.400 1060 191 22.3

16.00 4 40 0.050 28.800 7.200 795 159 33.0

Inox difficult 3.00 4 50 0.015 5.400 1.350 5305 318 2.3

[Cr-Ni-Mo++/1.4529] 4.00 4 50 0.020 7.200 1.800 3980 318 4.1

Heat resistant steel 5.00 4 50 0.030 9.000 2.250 3185 382 7.7

[1.4841] 6.00 4 50 0.035 10.800 2.700 2655 372 10.8

8.00 4 50 0.045 14.400 3.600 1990 358 18.6

10.00 4 50 0.055 18.000 4.500 1590 350 28.3

12.00 4 50 0.065 21.600 5.400 1325 345 40.2

16.00 4 50 0.070 28.800 7.200 995 279 57.8

PM high-speed steel 3.00 4 80 0.010 5.400 1.350 8490 340 2.5

annealed 4.00 4 80 0.015 7.200 1.800 6365 382 4.9

[Böhler S390] 5.00 4 80 0.020 9.000 2.250 5095 408 8.3

[ASP 2023] 6.00 4 80 0.020 10.800 2.700 4245 340 9.9

8.00 4 80 0.030 14.400 3.600 3185 382 19.8

10.00 4 80 0.035 18.000 4.500 2545 356 28.9

12.00 4 80 0.045 21.600 5.400 2120 382 44.5

16.00 4 80 0.050 28.800 7.200 1590 318 65.9

Titanium alloys 3.00 4 70 0.010 5.400 1.350 7425 297 2.2

> 300 HB 4.00 4 70 0.015 7.200 1.800 5570 334 4.3

[Ti6Al4V] 5.00 4 70 0.015 9.000 2.250 4455 267 5.4

6.00 4 70 0.020 10.800 2.700 3715 297 8.7

8.00 4 70 0.025 14.400 3.600 2785 279 14.4

10.00 4 70 0.035 18.000 4.500 2230 312 25.3

12.00 4 70 0.040 21.600 5.400 1855 297 34.6

16.00 4 70 0.045 28.800 7.200 1395 251 52.1

Nickel-based alloys 3.00 4 25 0.010 3.750 3.000 2655 106 1.2

annealed 4.00 4 25 0.010 5.000 4.000 1990 80 1.6

Rm <1000 N/mm² 5.00 4 25 0.015 6.250 5.000 1590 95 3.0

[Inconel 718] 6.00 4 25 0.015 7.500 6.000 1325 80 3.6

8.00 4 25 0.025 10.000 8.000 995 100 8.0

10.00 4 25 0.030 12.500 10.000 795 95 11.9

12.00 4 25 0.035 15.000 12.000 665 93 16.8

16.00 4 25 0.040 20.000 16.000 495 79 25.3

Nickel-based alloys 3.00 4 20 0.005 3.750 3.000 2120 42 0.5

precipitation hardened 4.00 4 20 0.010 5.000 4.000 1590 64 1.3

Rm > 1000 N/mm² 5.00 4 20 0.010 6.250 5.000 1275 51 1.6

[Inconel 718] 6.00 4 20 0.015 7.500 6.000 1060 64 2.9

8.00 4 20 0.020 10.000 8.000 795 64 5.1

10.00 4 20 0.020 12.500 10.000 635 51 6.4

12.00 4 20 0.025 15.000 12.000 530 53 9.5

16.00 4 20 0.030 20.000 16.000 400 48 15.4

fraisa.com

160