Page 189 - GARR_TOOL(CATALOG_INT)

P. 189

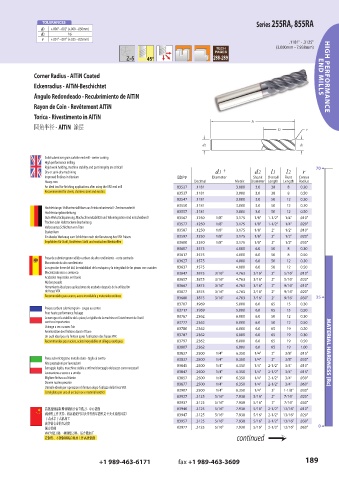

TOLERANCES Series 255RA, 855RA

d1 +.000" –.002" (+.000 –.050mm)

d2 h6

r +.001" –.001" (+.025 –.025mm)

.1181" - .3125"

(3.000mm - 7.938mm)

288-289

Corner Radius - AlTiN Coated END MILLS HIGH PERFORMANCE

Eckenradius - AlTiN-Beschichtet

Ángulo Redondeado - Recubrimiento de AlTiN

Rayon de Coin - Revêtement AlTiN

Torica - Rivestimento in AlTiN

圆角半径 - 涂层

圆角半径 - AlTiN 涂层

Solid submicron grain carbide end mill - center cutting

High performance milling

Rigid work holding, machine stability and part integrity are critical! 70 6

Dry or semi-dry machining d1 † d2 l1 l2 r

Improved finishes in titanium EDP# Diameter Shank Overall Flute Corner

Heavy core Decimal Metric Diameter Length Length Radius

An ideal tool for finishing applications after using the VRX end mill 83527 .1181 3.000 3.0 38 8 0.20

Recommended for steels, stainless steel and exotics 83537 .1181 3.000 3.0 38 8 0.50

83547 .1181 3.000 3.0 50 12 0.20

83550 .1181 3.000 3.0 50 12 0.30

Hochleistungs- Vollhartmetallfräser aus Feinkornhartmetall - Zentrumsschnitt

Hochleistungsbearbeitung 83557 .1181 3.000 3.0 50 12 0.50

Gute Werkstückspannung, Machschinenstabilität und Teileintegration sind entscheidend ! 83567 .1250 1/8" 3.175 1/8" 1-1/2" 1/4" .010"

Trocken oder Halbtrockene Bearbeitung 83577 .1250 1/8" 3.175 1/8" 1-1/2" 1/4" .020"

Verbessertes Schlichten von Titan

Starker Kern 83587 .1250 1/8" 3.175 1/8" 2" 1/2" .010"

Ein ideales Werkzeug zum Schlichten nach der Benutzung des VRX Fräsers 83597 .1250 1/8" 3.175 1/8" 2" 1/2" .020"

Empfohlen für Stahl, Rostfreiem Stahl und exotischen Werkstoffen 83600 .1250 1/8" 3.175 1/8" 2" 1/2" .030"

83607 .1575 4.000 6.0 50 8 0.30

83617 .1575 4.000 6.0 50 8 0.50

Fresa de submicrograno sólido carburo de alto rendimiento - corte centrado

Mecanizado de alto rendimiento 83627 .1575 4.000 6.0 50 12 0.30

La sujección firme del útil, la estabilidad de la máquina y la integridad de las piezas son cruciales 83637 .1575 4.000 6.0 50 12 0.50

Mecanizado seco o semiseco 83647 .1875 3/16" 4.763 3/16" 2" 5/16" .010"

Acabados mejorados en titanio 83657 .1875 3/16" 4.763 3/16" 2" 5/16" .020"

Núcleo pesado

Herramienta ideal para aplicaciones de acabado después de la utilización 83667 .1875 3/16" 4.763 3/16" 2" 9/16" .010"

de fresas VRX 83677 .1875 3/16" 4.763 3/16" 2" 9/16" .020"

Recomendado para aceros, acero inoxidable y materiales exóticos 35

83680 .1875 3/16" 4.763 3/16" 2" 9/16" .030" 6

83707 .1969 5.000 6.0 65 15 0.30

Fraises carbure submicrograin - coupe au centre 83717 .1969 5.000 6.0 65 15 0.50

Pour haute performance fraisage

Le serrage et la stabilite de la piece, la rigidite de la machine et l’atatchment de l’outil 83767 .2362 6.000 6.0 50 12 0.30

sont tres importantes 83777 .2362 6.000 6.0 50 12 0.50

Usinage a sec ou avec l’air 83780 .2362 6.000 6.0 65 19 0.20

Amelioration des finitions dans le Titane

Un outil ideal pour la finition apres l’utilisation des fraises VRX 83787 .2362 6.000 6.0 65 19 0.30

Recommandee pour aciers, aciers inoxydables et alliages exotiques 83797 .2362 6.000 6.0 65 19 0.50

83807 .2362 6.000 6.0 65 19 1.00

83827 .2500 1/4" 6.350 1/4" 2" 3/8" .015" MATERIAL HARDNESS (Rc)

Fresa sub-micrograno metallo duro - taglio al centro 83837 .2500 1/4" 6.350 1/4" 2" 3/8" .030"

Alte prestazioni per lavorazioni 83845 .2500 1/4" 6.350 1/4" 2-1/2" 3/4" .010"

Serraggio rigido, macchina stabile e ottimo bloccaggio del pezzo sono necessari!

Lavorazione a secco o a umido 83847 .2500 1/4" 6.350 1/4" 2-1/2" 3/4" .015"

Migliore finitura sul titanio 83857 .2500 1/4" 6.350 1/4" 2-1/2" 3/4" .030"

Dovere nucleo pesante 83877 .2500 1/4" 6.350 1/4" 2-1/2" 3/4" .060"

Utensile ideale per operazioni di finitura dopo l’utilizzo della fresa VRX

Consigliata per una di acciai, inox e materiali esotici 83907 .2500 1/4" 6.350 1/4" 3" 1-1/8" .030"

83927 .3125 5/16" 7.938 5/16" 2" 7/16" .020"

83937 .3125 5/16" 7.938 5/16" 2" 7/16" .030"

高效超细晶粒整体硬质合金立铣刀 - 中心切削 83940 .3125 5/16" 7.938 5/16" 2-1/2" 13/16" .010"

高刚性工件夹持、机床稳定性以及零件的牢固性是至关重要的因素! 83947 .3125 5/16" 7.938 5/16" 2-1/2" 13/16" .020"

干式或半干式机加工

改善钛合金的光洁度 83957 .3125 5/16" 7.938 5/16" 2-1/2" 13/16" .030" 0

强力芯部 83977 .3125 5/16" 7.938 5/16" 2-1/2" 13/16" .060" 6

VRX立铣刀是一种理想刀具,适合精加工

在钢件、不锈钢和稀有材质上作高效铣削 continued ?

+1 989-463-6171 fax +1 989-463-3609 189