Page 299 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 299

USER GUIDE

GUNDRILLS

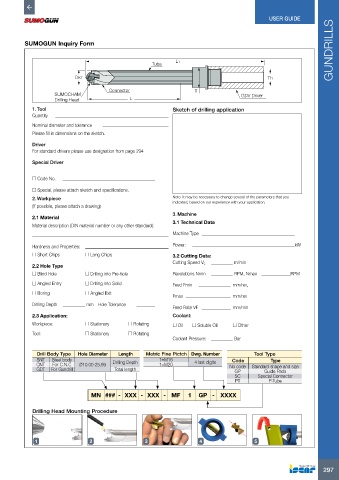

SUMOGUN Inquiry Form

Tube L1

Dk7 Th

Connector T

SUMOCHAM GDV Driver

Drilling Head L

1. Tool Sketch of drilling application

Quantity

Nominal diameter and tolerance

Please fill in dimensions on the sketch.

Driver

For standard drivers please use designation from page 294

Special Driver

o Code No.

o Special, please attach sketch and specifications.

2. Workpiece Note: It may be necessary to change several of the parameters that you

indicated, based on our experience with your application.

(If possible, please attach a drawing)

3. Machine

2.1 Material

3.1 Technical Data

Material description (DIN material number or any other standard):

Machine Type

Hardness and Properties: Power: kW

o Short Chips o Long Chips 3.2 Cutting Data:

Cutting Speed Vc m/min

2.2 Hole Type

o Blind Hole o Drilling into Pre-hole Revolutions Nmin RPM, Nmax RPM

o Angled Entry o Drilling into Solid Feed Fmin mm/rev,

o Boring o Angled Exit

Fmax mm/rev

Drilling Depth mm Hole Tolerance

Feed Rate VF mm/min

2.3 Application: Coolant:

Workpiece: o Stationary o Rotating o Oil o Soluble Oil o Other

Tool: o Stationary o Rotating

Coolant Pressure: Bar

Drill Body Type Hole Diameter Length Metric Fine Pictch Dwg. Number Tool Type

SNT Steel body 1=M16 Code Type

CNT For C.N.C Ø10.00-25.99 Drilling Depth 1=M20 4 last digits No code Standard shape and size

GDT For Gundrill Total length GP Guide Pads

SC Special Connector

PT P-Tube

MN ### - XXX - XXX - MF 1 GP - XXXX

Drilling Head Mounting Procedure

1 2 3 4 5

297