Page 300 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 300

USER GUIDE

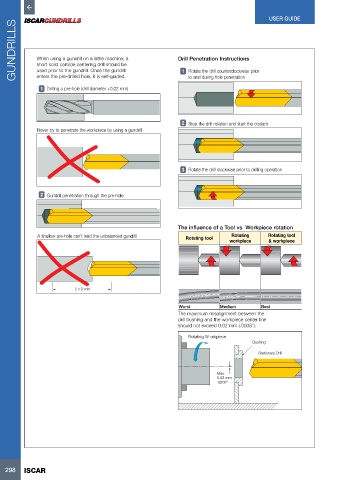

GUNDRILLS When using a gundrill on a lathe machine, a Drill Penetration Instructions

short solid carbide centering drill should be

used prior to the gundrill. Once the gundrill

enters the pre-drilled hole, it is self-guided.

to and during hole penetration

1 Drilling a pre-hole (drill diameter +0.02 mm) 1 Rotate the drill counterclockwise prior

2 Stop the drill rotation and start the coolant

Never try to penetrate the workpiece by using a gundrill

3 Rotate the drill clockwise prior to drilling operation

2 Gundrill penetration through the pre-hole

The influence of a Tool vs. Workpiece rotation

A shallow pre-hole can’t lead the unbalanced gundrill Rotating tool Rotating Rotating tool

workpiece & workpiece

2 x D min

Worst Medium Best

The maximum misalignment between the

drill bushing and the workpiece center line

should not exceed 0.02 mm (.0008”).

Rotating W orkpiece

Bushing

Stationary Drill

Max.

0.02 mm

.0008"

298 ISCAR