Page 131 - ISCAR(MILLINGCATALOG 38_2021)

P. 131

CHW x 45° Rd°

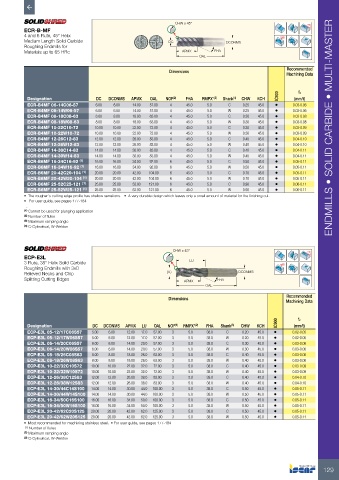

ECR-B-MF

4 and 6 Flute, 45° Helix

Medium Length Solid Carbide DC DCONMS

Roughing Endmills for

Materials up to 65 HRc APMX FHA

OAL

Dimensions Recommended

Machining Data

IC900 fz

Designation DC DCONMS APMX OAL NOF (2) FHA RMPX° (3) Shank (4) CHW KCH (mm/t)

ECR-B4MF 06-14C06-57 6.00 6.00 14.00 57.00 4 45.0 5.0 C 0.25 45.0 • 0.03-0.06

ECR-B4MF 06-14W06-57 6.00 6.00 14.00 57.00 4 45.0 5.0 W 0.25 45.0 • 0.03-0.06

ECR-B4MF 08-18C08-63 8.00 8.00 18.00 63.00 4 45.0 5.0 C 0.30 45.0 • 0.03-0.08

ECR-B4MF 08-18W08-63 8.00 8.00 18.00 63.00 4 45.0 5.0 W 0.30 45.0 • 0.03-0.08

ECR-B4MF 10-22C10-72 10.00 10.00 22.00 72.00 4 45.0 5.0 C 0.30 45.0 • 0.03-0.09 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

ECR-B4MF 10-22W10-72 10.00 10.00 22.00 72.00 4 45.0 5.0 W 0.30 45.0 • 0.03-0.09

ECR-B4MF 12-26C12-83 12.00 12.00 26.00 83.00 4 45.0 5.0 C 0.40 45.0 • 0.04-0.10

ECR-B4MF 12-26W12-83 12.00 12.00 26.00 83.00 4 45.0 5.0 W 0.40 45.0 • 0.04-0.10

ECR-B4MF 14-30C14-83 14.00 14.00 30.00 83.00 4 45.0 5.0 C 0.40 45.0 • 0.04-0.11

ECR-B4MF 14-30W14-83 14.00 14.00 30.00 83.00 4 45.0 5.0 W 0.40 45.0 • 0.04-0.11

ECR-B6MF 16-34C16-92 (1) 16.00 16.00 34.00 92.00 6 45.0 5.0 C 0.50 45.0 • 0.05-0.11

ECR-B6MF 16-34W16-92 (1) 16.00 16.00 34.00 92.00 6 45.0 5.0 W 0.50 45.0 • 0.05-0.11

ECR-B6MF 20-42C20-104 (1) 20.00 20.00 42.00 104.00 6 45.0 5.0 C 0.70 45.0 • 0.05-0.11

ECR-B6MF 20-42W20-104 (1) 20.00 20.00 42.00 104.00 6 45.0 5.0 W 0.70 45.0 • 0.05-0.11

ECR-B6MF 25-52C25-121 (1) 25.00 25.00 52.00 121.00 6 45.0 5.0 C 0.90 45.0 • 0.06-0.11

ECR-B6MF 25-52W25-121 (1) 25.00 25.00 52.00 121.00 6 45.0 5.0 W 0.90 45.0 • 0.06-0.11

• The rougher's cutting edge profile has shallow serrations. • A very durable design which leaves only a small amount of material for the finishing cut.

• For user guide, see pages 177-184

..

(1) Cannot be used for plunging application

(2) Number of flutes

(3) Maximum ramping angle

(4) C-Cylindrical, W-Weldon

CHW x 45° Rd°

ECP-E3L

3 Flute, 38° Helix Solid Carbide LU

Roughing Endmills with 3xD

Relieved Necks and Chip DC DCONMS

Splitting Cutting Edges APMX FHA

OAL

Recommended

Dimensions

Machining Data

IC900 fz

Designation DC DCONMS APMX LU OAL NOF (1) RMPX° (2) FHA Shank (3) CHW KCH (mm/t)

ECP-E3L 05-12/17C06S57 5.00 6.00 12.00 17.0 57.00 3 5.0 38.0 C 0.20 45.0 • 0.02-0.05

ECP-E3L 05-12/17W06S57 5.00 6.00 12.00 17.0 57.00 3 5.0 38.0 W 0.20 45.0 • 0.02-0.05

ECP-E3L 06-14/20C06S57 6.00 6.00 14.00 20.0 57.00 3 5.0 38.0 C 0.30 45.0 • 0.03-0.06

ECP-E3L 06-14/20W06S57 6.00 6.00 14.00 20.0 57.00 3 5.0 38.0 W 0.30 45.0 • 0.03-0.06

ECP-E3L 08-18/26C08S63 8.00 8.00 18.00 26.0 63.00 3 5.0 38.0 C 0.40 45.0 • 0.03-0.08

ECP-E3L 08-18/26W08S63 8.00 8.00 18.00 26.0 63.00 3 5.0 38.0 W 0.40 45.0 • 0.03-0.08

ECP-E3L 10-22/32C10S72 10.00 10.00 22.00 32.0 72.00 3 5.0 38.0 C 0.40 45.0 • 0.03-0.09

ECP-E3L 10-22/32W10S72 10.00 10.00 22.00 32.0 72.00 3 5.0 38.0 W 0.40 45.0 • 0.03-0.09

ECP-E3L 12-26/38C12S83 12.00 12.00 26.00 38.0 83.00 3 5.0 38.0 C 0.40 45.0 • 0.04-0.10

ECP-E3L 12-26/38W12S83 12.00 12.00 26.00 38.0 83.00 3 5.0 38.0 W 0.40 45.0 • 0.04-0.10

ECP-E3L 14-30/44C14S100 14.00 14.00 30.00 44.0 100.00 3 5.0 38.0 C 0.50 45.0 • 0.05-0.11

ECP-E3L 14-30/44W14S100 14.00 14.00 30.00 44.0 100.00 3 5.0 38.0 W 0.50 45.0 • 0.05-0.11

ECP-E3L 16-34/50C16S100 16.00 16.00 34.00 50.0 100.00 3 5.0 38.0 C 0.50 45.0 • 0.05-0.11

ECP-E3L 16-34/50W16S100 16.00 16.00 34.00 50.0 100.00 3 5.0 38.0 W 0.50 45.0 • 0.05-0.11

ECP-E3L 20-42/62C20S125 20.00 20.00 42.00 62.0 125.00 3 5.0 38.0 C 0.50 45.0 • 0.05-0.11

ECP-E3L 20-42/62W20S125 20.00 20.00 42.00 62.0 125.00 3 5.0 38.0 W 0.50 45.0 • 0.05-0.11

• Most recommended for machining stainless steel. • For user guide, see pages 177-184

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical, W-Weldon

129