Page 133 - ISCAR(MILLINGCATALOG 38_2021)

P. 133

CHW x 45° Rd°

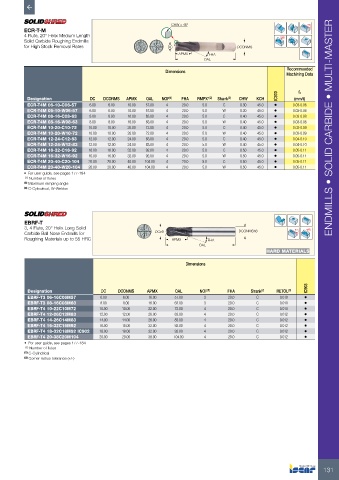

ECR-T-M

4 Flute, 20° Helix Medium Length

Solid Carbide Roughing Endmills

for High Stock Removal Rates DC DCONMS

APMX FHA

OAL

Dimensions Recommended

Machining Data

IC900 fz

Designation DC DCONMS APMX OAL NOF (1) FHA RMPX° (2) Shank (3) CHW KCH (mm/t)

ECR-T4M 06-10-C06-57 6.00 6.00 10.00 57.00 4 20.0 5.0 C 0.30 45.0 • 0.03-0.06

ECR-T4M 06-10-W06-57 6.00 6.00 10.00 57.00 4 20.0 5.0 W 0.30 45.0 • 0.03-0.06

ECR-T4M 08-16-C08-63 8.00 8.00 16.00 63.00 4 20.0 5.0 C 0.40 45.0 • 0.03-0.08

ECR-T4M 08-16-W08-63 8.00 8.00 16.00 63.00 4 20.0 5.0 W 0.40 45.0 • 0.03-0.08

ECR-T4M 10-20-C10-72 10.00 10.00 20.00 72.00 4 20.0 5.0 C 0.40 45.0 • 0.03-0.09 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

ECR-T4M 10-20-W10-72 10.00 10.00 20.00 72.00 4 20.0 5.0 W 0.40 45.0 • 0.03-0.09

ECR-T4M 12-24-C12-83 12.00 12.00 24.00 83.00 4 20.0 5.0 C 0.40 45.0 • 0.04-0.10

ECR-T4M 12-24-W12-83 12.00 12.00 24.00 83.00 4 20.0 5.0 W 0.40 45.0 • 0.04-0.10

ECR-T4M 16-32-C16-92 16.00 16.00 32.00 92.00 4 20.0 5.0 C 0.50 45.0 • 0.05-0.11

ECR-T4M 16-32-W16-92 16.00 16.00 32.00 92.00 4 20.0 5.0 W 0.50 45.0 • 0.05-0.11

ECR-T4M 20-40-C20-104 20.00 20.00 40.00 104.00 4 20.0 5.0 C 0.50 45.0 • 0.05-0.11

ECR-T4M 20-40-W20-104 20.00 20.00 40.00 104.00 4 20.0 5.0 W 0.50 45.0 • 0.05-0.11

• For user guide, see pages 177-184

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical, W-Weldon

EBRF-T

3, 4 Flute, 20° Helix Long Solid Rd°

Carbide Ball Nose Endmills for DCe9 DCONMSh6

Roughing Materials up to 55 HRC APMX FHA

OAL

HARD MATERIALS

Dimensions

IC903

Designation DC DCONMS APMX OAL NOF (1) FHA Shank (2) RETOL (3)

EBRF-T3 06-16C06M57 6.00 6.00 16.00 57.00 3 20.0 C 0.010 •

EBRF-T3 08-16C08M63 8.00 8.00 16.00 63.00 3 20.0 C 0.010 •

EBRF-T4 10-22C10M72 10.00 10.00 22.00 72.00 4 20.0 C 0.010 •

EBRF-T4 12-26C12M83 12.00 12.00 26.00 83.00 4 20.0 C 0.012 •

EBRF-T4 14-26C14M83 14.00 14.00 26.00 83.00 4 20.0 C 0.012 •

EBRF-T4 16-32C16M92 16.00 16.00 32.00 92.00 4 20.0 C 0.012 •

EBRF-T4 18-32C18M92 IC902 18.00 18.00 32.00 92.00 4 20.0 C 0.012 •

EBRF-T4 20-38C20M104 20.00 20.00 38.00 104.00 4 20.0 C 0.012 •

• For user guide, see pages 177-184

(1) Number of flutes

(2) C-Cylindrical

(3) Corner radius tolerance (+/-)

131