Page 165 - ISCAR(MILLINGCATALOG 38_2021)

P. 165

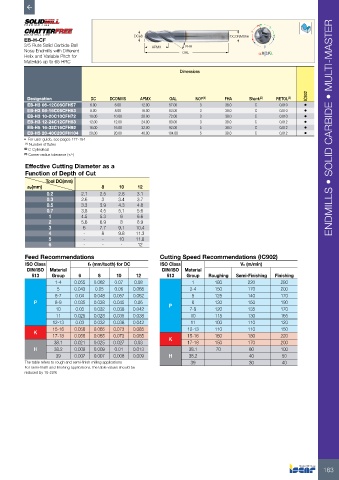

DCe8 DCONMSh6 α λ

EB-H-CF

3/5 Flute Solid Carbide Ball APMX FHA β

Nose Endmills with Different OAL α#β#λ

Helix and Variable Pitch for

Materials up to 65 HRC

Dimensions

IC902

Designation DC DCONMS APMX OAL NOF (1) FHA Shank (2) RETOL (3)

EB-H3 06-12C06CFH57 6.00 6.00 12.00 57.00 3 38.0 C 0.010 •

EB-H3 08-16C08CFH63 8.00 8.00 16.00 63.00 3 38.0 C 0.010 •

EB-H3 10-20C10CFH72 10.00 10.00 20.00 72.00 3 38.0 C 0.010 •

EB-H3 12-24C12CFH83 12.00 12.00 24.00 83.00 3 38.0 C 0.012 •

EB-H5 16-32C16CFH92 16.00 16.00 32.00 92.00 5 38.0 C 0.012 • ENDMILLS • SOLID CARBIDE • MULTI-MASTER

EB-H5 20-40C20CFH104 20.00 20.00 40.00 104.00 5 38.0 C 0.012 •

• For user guide, see pages 177-184

(1) Number of flutes

(2) C-Cylindrical

(3) Corner radius tolerance (+/-)

Effective Cutting Diameter as a

Function of Depth of Cut

Tool DC(mm)

ap(mm) 8 10 12

0.2 2.1 2.5 2.8 3.1

0.3 2.6 3 3.4 3.7

0.5 3.3 3.9 4.3 4.8

0.7 3.8 4.5 5.1 5.6

1 4.5 5.3 6 6.6

2 5.6 6.9 8 8.9

3 6 7.7 9.1 10.4

4 - 8 9.8 11.3

5 - - 10 11.8

6 - - - 12

Feed Recommendations Cutting Speed Recommendations (IC902)

ISO Class fz (mm/tooth) for DC ISO Class Vc (m/min)

DIN/ISO Material DIN/ISO Material

513 Group 6 8 10 12 513 Group Roughing Semi-Finishing Finishing

1-4 0.055 0.062 0.07 0.08 1 180 220 280

5 0.043 0.05 0.06 0.068 2-4 150 170 200

6-7 0.04 0.048 0.057 0.062 5 125 140 170

P 8-9 0.035 0.038 0.045 0.05 P 6 130 150 190

10 0.03 0.032 0.038 0.042 7-9 120 135 170

11 0.025 0.028 0.035 0.038 10 115 130 165

12-13 0.03 0.032 0.038 0.042 11 100 110 120

15-16 0.058 0.065 0.073 0.085 12-13 110 110 150

K

17-18 0.058 0.065 0.073 0.085 K 15-16 160 180 220

38.1 0.021 0.025 0.027 0.03 17-18 150 170 200

H 38.2 0.008 0.009 0.01 0.013 38.1 70 80 100

39 0.007 0.007 0.008 0.009 H 38.2 40 50

The table refers to rough and semi-finish milling applications 39 30 40

For semi-finish and finishing applications, the table values should be

reduced by 10-20%

163