Page 163 - ISCAR(MILLINGCATALOG 38_2021)

P. 163

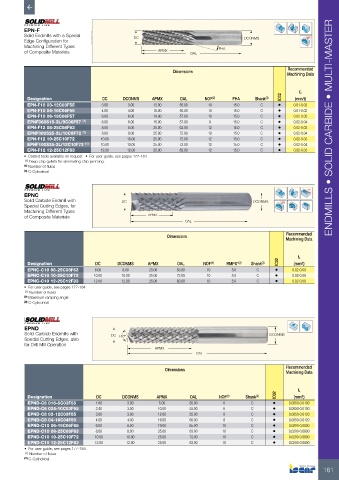

EPN-F

Solid Endmills with a Special DC DCONMS

Edge Configuration for

Machining Different Types FHA

of Composite Materials APMX OAL

Dimensions Recommended

Machining Data

fz

Designation DC DCONMS APMX OAL NOF (2) FHA Shank (3) IC02 (mm/t)

EPN-F10 03-12C03F55 3.00 3.00 12.00 55.00 10 15.0 C • 0.01-0.02

EPN-F10 04-16C04F55 4.00 4.00 16.00 55.00 10 15.0 C • 0.01-0.02

EPN-F10 06-19C06F57 6.00 6.00 19.00 57.00 10 15.0 C • 0.02-0.03

EPNF060S15-3L/9C06F57 (1) 6.00 6.00 15.00 57.00 9 15.0 C • 0.02-0.04

EPN-F12 08-25C08F63 8.00 8.00 25.00 63.00 12 15.0 C • 0.02-0.03 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

EPNF080S25-3L/10C8F72 (1) 8.00 8.00 25.00 72.00 10 15.0 C • 0.02-0.04

EPN-F12 10-25C10F72 10.00 10.00 25.00 72.00 12 15.0 C • 0.02-0.03

EPNF100S25-3L/12C10F72 (1) 10.00 10.00 25.00 72.00 12 15.0 C • 0.02-0.04

EPN-F12 12-25C12F83 12.00 12.00 25.00 83.00 12 15.0 C • 0.02-0.03

• Coated tools available on request • For user guide, see pages 177-184

(1) Deep chip gullets for eliminating chip jamming.

(2) Number of flutes

(3) C-Cylindrical

Rd°

EPNC

Solid Carbide Endmill with DC DCONMS

Special Cutting Edges, for

Machining Different Types

of Composite Materials APMX

OAL

Recommended

Dimensions

Machining Data

fz

Designation DC DCONMS APMX OAL NOF (1) RMPX° (2) Shank (3) IC02 (mm/t)

EPNC-C10 08-25C08F63 8.00 8.00 25.00 63.00 10 5.0 C • 0.02-0.08

EPNC-C10 10-25C10F72 10.00 10.00 25.00 72.00 10 5.0 C • 0.02-0.08

EPNC-C10 12-25C12F83 12.00 12.00 25.00 83.00 10 5.0 C • 0.02-0.08

• For user guide, see pages 177-184

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical

EPND

Solid Carbide Endmills with DC 140° DCONMS

Special Cutting Edges, also

for Drill Mill Operation

APMX

OAL

Recommended

Dimensions

Machining Data

fz

Designation DC DCONMS APMX OAL NOF (1) Shank (2) IC02 (mm/t)

EPND-C6 016-5C03F55 1.60 3.00 5.00 55.00 6 C • 0.0050-0.0100

EPND-C6 024-10C03F55 2.40 3.00 10.00 55.00 6 C • 0.0050-0.0100

EPND-C8 03-12C03F55 3.00 3.00 12.00 55.00 8 C • 0.0050-0.0120

EPND-C8 04-16C04F60 4.00 4.00 16.00 60.00 8 C • 0.0050-0.0120

EPND-C10 06-19C06F65 6.00 6.00 19.00 65.00 10 C • 0.0200-0.0800

EPND-C10 08-25C08F63 8.00 8.00 25.00 63.00 10 C • 0.0200-0.0800

EPND-C10 10-25C10F72 10.00 10.00 25.00 72.00 10 C • 0.0200-0.0800

EPND-C10 12-25C12F83 12.00 12.00 25.00 83.00 10 C • 0.0200-0.0800

• For user guide, see pages 177-184

(1) Number of flutes

(2) C-Cylindrical

161