Page 159 - ISCAR(MILLINGCATALOG 38_2021)

P. 159

Rd°

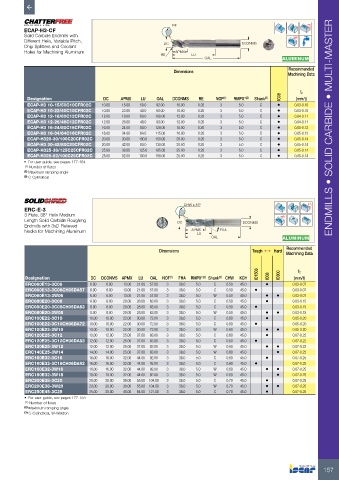

ECAP-H3-CF RE

Solid Carbide Endmills with

Different Helix, Variable Pitch, DC DCONMS

Chip Splitters and Coolant

Holes for Machining Aluminum APMX

RE LU

OAL ALUMINUM

Dimensions Recommended

Machining Data

fz

Designation DC APMX LU OAL DCONMS RE NOF (1) RMPX° (2) Shank (3) IC08 (mm/t)

ECAP-H3 10-15/50C10CFR02C 10.00 15.00 50.0 92.00 10.00 0.20 3 5.0 C • 0.03-0.10

ECAP-H3 10-22/40C10CFR02C 10.00 22.00 40.0 80.00 10.00 0.20 3 5.0 C • 0.03-0.10

ECAP-H3 12-18/60C12CFR02C 12.00 18.00 60.0 100.00 12.00 0.20 3 5.0 C • 0.04-0.11

ECAP-H3 12-26/48C12CFR02C 12.00 26.00 48.0 93.00 12.00 0.20 3 5.0 C • 0.04-0.11

ECAP-H3 16-24/80C16CFR02C 16.00 24.00 80.0 128.00 16.00 0.20 3 5.0 C • 0.05-0.13 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

ECAP-H3 16-34/64C16CFR02C 16.00 34.00 64.0 115.00 16.00 0.20 3 5.0 C • 0.05-0.13

ECAP-H320-30/100C20CFR02C 20.00 30.00 100.0 150.00 20.00 0.20 3 5.0 C • 0.05-0.14

ECAP-H3 20-42/80C20CFR02C 20.00 42.00 80.0 130.00 20.00 0.20 3 5.0 C • 0.05-0.14

ECAP-H325-38/125C25CFR02C 25.00 38.00 125.0 185.00 25.00 0.20 3 5.0 C • 0.05-0.14

ECAP-H325-52/100C25CFR02C 25.00 52.00 100.0 158.00 25.00 0.20 3 5.0 C • 0.05-0.14

• For user guide, see pages 177-184

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical

CHW x 45° Rd°

ERC-E-3

3 Flute, 38° Helix Medium

Length Solid Carbide Roughing DC DCONMS

Endmills with 3xD Relieved

Necks for Machining Aluminum APMX FHA

LU

OAL ALUMINUM

Recommended

Dimensions Tough 1 Hard Machining Data

IC1508 IC300 fz

Designation DC DCONMS APMX LU OAL NOF (1) FHA RMPX° (2) Shank (3) CHW KCH IC08 (mm/t)

ERC060E13-3C06 6.00 6.00 13.00 21.00 57.00 3 38.0 5.0 C 0.50 45.0 • 0.03-0.07

ERC060E13-3C06CH05DA57 6.00 6.00 13.00 21.00 57.00 3 38.0 5.0 C 0.50 45.0 • 0.03-0.07

ERC060E13-3W06 6.00 6.00 13.00 21.00 57.00 3 38.0 5.0 W 0.50 45.0 • • 0.03-0.07

ERC080E20-3C08 8.00 8.00 20.00 28.00 63.00 3 38.0 5.0 C 0.50 45.0 • 0.03-0.15

ERC080E20-3C08CH05DA63 8.00 8.00 20.00 28.00 63.00 3 38.0 5.0 C 0.50 45.0 • 0.03-0.15

ERC080E20-3W08 8.00 8.00 20.00 28.00 63.00 3 38.0 5.0 W 0.50 45.0 • • 0.03-0.15

ERC100E22-3C10 10.00 10.00 22.00 30.00 72.00 3 38.0 5.0 C 0.60 45.0 • 0.05-0.20

ERC100E22-3C10CH06DA72 10.00 10.00 22.00 30.00 72.00 3 38.0 5.0 C 0.60 45.0 • 0.05-0.20

ERC100E22-3W10 10.00 10.00 22.00 30.00 72.00 3 38.0 5.0 W 0.60 45.0 • • 0.05-0.20

ERC120E25-3C12 12.00 12.00 25.00 37.00 83.00 3 38.0 5.0 C 0.60 45.0 • 0.07-0.22

ERC120E25-3C12CH06DA83 12.00 12.00 25.00 37.00 83.00 3 38.0 5.0 C 0.60 45.0 • 0.07-0.22

ERC120E25-3W12 12.00 12.00 25.00 37.00 83.00 3 38.0 5.0 W 0.60 45.0 • • 0.07-0.22

ERC140E25-3W14 14.00 14.00 25.00 37.00 83.00 3 38.0 5.0 W 0.60 45.0 • 0.07-0.22

ERC160E32-3C16 16.00 16.00 32.00 44.00 92.00 3 38.0 5.0 C 0.60 45.0 • 0.07-0.25

ERC160E32-3C16CH06DA92 16.00 16.00 32.00 44.00 92.00 3 38.0 5.0 C 0.60 45.0 • 0.07-0.25

ERC160E32-3W16 16.00 16.00 32.00 44.00 92.00 3 38.0 5.0 W 0.60 45.0 • • 0.07-0.25

ERC180E32-3W18 18.00 18.00 32.00 44.00 92.00 3 38.0 5.0 W 0.60 45.0 • 0.07-0.25

ERC200E38-3C20 20.00 20.00 38.00 55.00 104.00 3 38.0 5.0 C 0.70 45.0 • 0.07-0.25

ERC200E38-3W20 20.00 20.00 38.00 55.00 104.00 3 38.0 5.0 W 0.70 45.0 • • 0.07-0.25

ERC250E45-3C25 25.00 25.00 45.00 64.00 121.00 3 38.0 5.0 C 0.70 45.0 • 0.07-0.25

• For user guide, see pages 177-184

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical, W-Weldon

157