Page 166 - ISCAR(MILLINGCATALOG 38_2021)

P. 166

Rd°

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

DCe8 DCONMSh6 α β

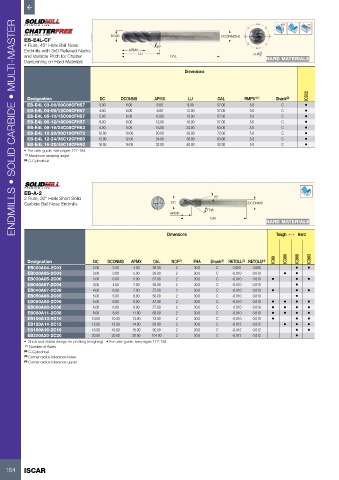

EB-E4L-CF

4 Flute, 45° Helix Ball Nose 45° β α

Endmills with 3xD Relieved Necks APMX LU α≠β

and Variable Pitch for Chatter OAL HARD MATERIALS

Dampening on Hard Materials

Dimensions

IC902

Designation DC DCONMS APMX LU OAL RMPX° (1) Shank (2)

EB-E4L 03-06/09C06CFH57 3.00 6.00 6.00 9.00 57.00 5.0 C •

EB-E4L 04-08/12C06CFH57 4.00 6.00 8.00 12.00 57.00 5.0 C •

EB-E4L 05-10/15C06CFH57 5.00 6.00 10.00 15.00 57.00 5.0 C •

EB-E4L 06-12/18C06CFH57 6.00 6.00 12.00 18.00 57.00 5.0 C •

EB-E4L 08-16/24C08CFH63 8.00 8.00 16.00 24.00 63.00 5.0 C •

EB-E4L 10-20/30C10CFH72 10.00 10.00 20.00 30.00 72.00 5.0 C •

EB-E4L 12-24/36C12CFH83 12.00 12.00 24.00 36.00 83.00 5.0 C •

EB-E4L 16-32/48C16CFH92 16.00 16.00 32.00 48.00 92.00 5.0 C •

• For user guide, see pages 177-184

(1) Maximum ramping angle

(2) C-Cylindrical

EB-A-2

2 Flute, 30° Helix Short Solid 15°

Carbide Ball Nose Endmills DC DCONMS

FHA

APMX

OAL

HARD MATERIALS

Dimensions Tough 1 Hard

Designation DC DCONMS APMX OAL NOF (1) FHA Shank (2) RETOLL (3) RETOLU (4) IC08 IC300 IC900 IC903

EB020A04-2C03 2.00 3.00 4.00 38.00 2 30.0 C 0.000 0.005 • •

EB030A05-2C03 3.00 3.00 5.00 38.00 2 30.0 C -0.010 0.010 • •

EB030A05-2C06 3.00 6.00 5.00 57.00 2 30.0 C -0.010 0.010 • • •

EB040A07-2C04 4.00 4.00 7.00 50.00 2 30.0 C -0.010 0.010 •

EB040A07-2C06 4.00 6.00 7.00 57.00 2 30.0 C -0.010 0.010 • • •

EB050A08-2C05 5.00 5.00 8.00 50.00 2 30.0 C -0.010 0.010 •

EB050A08-2C06 5.00 6.00 8.00 57.00 2 30.0 C -0.010 0.010 • • • •

EB060A08-2C06 6.00 6.00 8.00 57.00 2 30.0 C -0.010 0.010 • • • •

EB080A11-2C08 8.00 8.00 11.00 63.00 2 30.0 C -0.010 0.010 • • • •

EB100A13-2C10 10.00 10.00 13.00 72.00 2 30.0 C -0.010 0.010 • • •

EB120A14-2C12 12.00 12.00 14.00 83.00 2 30.0 C -0.012 0.012 • • •

EB160A16-2C16 16.00 16.00 16.00 92.00 2 30.0 C -0.012 0.012 • •

EB200A20-2C20 20.00 20.00 20.00 104.00 2 30.0 C -0.012 0.012 •

• Short and stable design for profiling (roughing). • For user guide, see pages 177-184

(1) Number of flutes

(2) C-Cylindrical

(3) Corner radius tolerance lower

(4) Corner radius tolerance upper

164 ISCAR