Page 173 - ISCAR(MILLINGCATALOG 38_2021)

P. 173

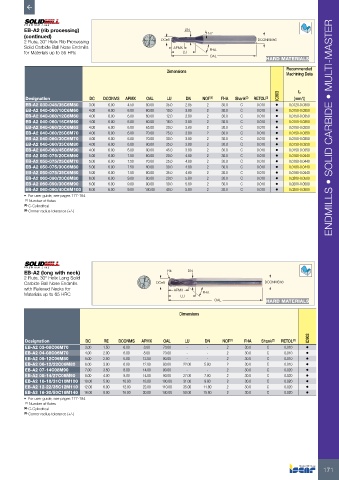

EB-A2 (rib processing) DN

(continued) 15°

2 Flute, 30° Helix Rib Processing DCe8 DCONMSh6

Solid Carbide Ball Nose Endmills APMX FHA

for Materials up to 55 HRc LU

OAL

HARD MATERIALS

Recommended

Dimensions

Machining Data

IC903 fz

Designation DC DCONMS APMX OAL LU DN NOF (1) FHA Shank (2) RETOL (3) (mm/t)

EB-A2 030-045/35C6M80 3.00 6.00 4.50 80.00 35.0 2.85 2 30.0 C 0.010 • 0.0120-0.0300

EB-A2 040-060/10C6M60 4.00 6.00 6.00 60.00 10.0 3.80 2 30.0 C 0.010 • 0.0150-0.0350

EB-A2 040-060/12C6M60 4.00 6.00 6.00 60.00 12.0 3.80 2 30.0 C 0.010 • 0.0150-0.0350

EB-A2 040-060/16C6M60 4.00 6.00 6.00 60.00 16.0 3.80 2 30.0 C 0.010 • 0.0150-0.0350

EB-A2 040-060/20C6M65 4.00 6.00 6.00 65.00 20.0 3.80 2 30.0 C 0.010 • 0.0150-0.0350 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

EB-A2 040-060/25C6M70 4.00 6.00 6.00 70.00 25.0 3.80 2 30.0 C 0.010 • 0.0150-0.0350

EB-A2 040-060/30C6M70 4.00 6.00 6.00 70.00 30.0 3.80 2 30.0 C 0.010 • 0.0150-0.0350

EB-A2 040-060/35C6M80 4.00 6.00 6.00 80.00 35.0 3.80 2 30.0 C 0.010 • 0.0150-0.0350

EB-A2 040-060/45C6M90 4.00 6.00 6.00 90.00 45.0 3.80 2 30.0 C 0.010 • 0.0150-0.0350

EB-A2 050-075/20C6M60 5.00 6.00 7.50 60.00 20.0 4.80 2 30.0 C 0.010 • 0.0180-0.0440

EB-A2 050-075/25C6M70 5.00 6.00 7.50 70.00 25.0 4.80 2 30.0 C 0.010 • 0.0180-0.0440

EB-A2 050-075/30C6M80 5.00 6.00 7.50 80.00 30.0 4.80 2 30.0 C 0.010 • 0.0180-0.0440

EB-A2 050-075/35C6M80 5.00 6.00 7.50 80.00 35.0 4.80 2 30.0 C 0.010 • 0.0180-0.0440

EB-A2 060-090/20C6M80 6.00 6.00 9.00 80.00 20.0 5.80 2 30.0 C 0.010 • 0.0200-0.0500

EB-A2 060-090/30C6M90 6.00 6.00 9.00 90.00 30.0 5.80 2 30.0 C 0.010 • 0.0200-0.0500

EB-A2 060-090/40C6M100 6.00 6.00 9.00 100.00 40.0 5.80 2 30.0 C 0.010 • 0.0200-0.0500

• For user guide, see pages 177-184

(1) Number of flutes

(2) C-Cylindrical

(3) Corner radius tolerance (+/-)

EB-A2 (long with neck) RE DN

2 Flute, 30° Helix Long Solid

Carbide Ball Nose Endmills DCe8 DCONMSh6

with Relieved Necks for APMX

Materials up to 65 HRC LU FHA

OAL HARD MATERIALS

Dimensions

IC903

Designation DC RE DCONMS APMX OAL LU DN NOF (1) FHA Shank (2) RETOL (3)

EB-A2 03-08C06M70 3.00 1.50 6.00 8.00 70.00 - - 2 30.0 C 0.010 •

EB-A2 04-08C06M70 4.00 2.00 6.00 8.00 70.00 - - 2 30.0 C 0.010 •

EB-A2 05-12C06M80 5.00 2.50 6.00 12.00 80.00 - - 2 30.0 C 0.010 •

EB-A2 06-12/22C06M80 6.00 3.00 6.00 12.00 80.00 22.00 5.80 2 30.0 C 0.010 •

EB-A2 07-14C08M90 7.00 3.50 8.00 14.00 90.00 - - 2 30.0 C 0.020 •

EB-A2 08-14/27C08M90 8.00 4.00 8.00 14.00 90.00 27.00 7.80 2 30.0 C 0.020 •

EB-A2 10-18/31C10M100 10.00 5.00 10.00 18.00 100.00 31.00 9.80 2 30.0 C 0.020 •

EB-A2 12-22/35C12M110 12.00 6.00 12.00 22.00 110.00 35.00 11.80 2 30.0 C 0.020 •

EB-A2 16-30/50C16M140 16.00 8.00 16.00 30.00 140.00 50.00 15.80 2 30.0 C 0.020 •

• For user guide, see pages 177-184

(1) Number of flutes

(2) C-Cylindrical

(3) Corner radius tolerance (+/-)

171