Page 196 - ISCAR(MILLINGCATALOG 38_2021)

P. 196

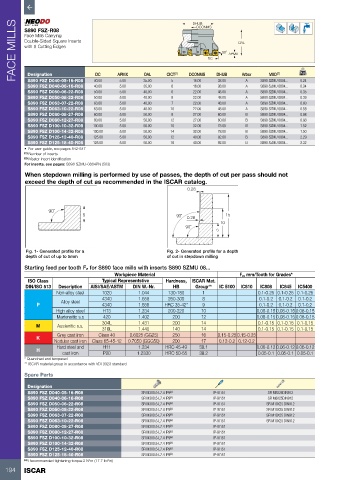

FACE MILLS S890 FSZ-R08 DHUB DC 90˚ APMX OAL

DCONMS

Face Mills Carrying

Double-Sided Square Inserts

with 8 Cutting Edges

kg

(2)

DC

OAL

Designation

MIID

S890 FSZ D040-05-16-R08

5.00

16.00

38.00

A

5

S890 FSZ D040-06-16-R08 40.00 APMX 35.00 CICT (1) DCONMS DHUB Arbor S890 SZMU 0804... 0.24

38.00

A

35.00

6

16.00

S890 SZMU 0804...

40.00

5.00

0.34

S890 FSZ D050-06-22-R08 50.00 5.00 40.00 6 22.00 48.00 A S890 SZMU 0804... 0.35

S890 FSZ D050-08-22-R08 50.00 5.00 40.00 8 22.00 48.00 A S890 SZMU 0804... 0.39

S890 FSZ D063-07-22-R08 63.00 5.00 40.00 7 22.00 48.00 A S890 SZMU 0804... 0.60

S890 FSZ D063-10-22-R08 63.00 5.00 40.00 10 22.00 48.00 A S890 SZMU 0804... 0.58

S890 FSZ D080-08-27-R08 80.00 5.00 50.00 8 27.00 60.00 B S890 SZMU 0804... 0.98

S890 FSZ D080-12-27-R08 80.00 5.00 50.00 12 27.00 60.00 B S890 SZMU 0804... 0.93

S890 FSZ D100-10-32-R08 100.00 5.00 50.00 10 32.00 78.00 B S890 SZMU 0804... 1.52

S890 FSZ D100-14-32-R08 100.00 5.00 50.00 14 32.00 78.00 B S890 SZMU 0804... 1.50

S890 FSZ D125-12-40-R08 125.00 5.00 50.00 12 40.00 92.00 B S890 SZMU 0804... 2.29

S890 FSZ D125-18-40-R08 125.00 5.00 50.00 18 40.00 92.00 B S890 SZMU 0804... 2.32

• For user guide, see pages 542-547

(1) Number of inserts

(2) Master insert identification

For inserts, see pages: S890 SZMU-0804PN (503)

When stepdown milling is performed by use of passes, the depth of cut per pass should not

exceed the depth of cut as recommended in the ISCAR catalog.

0.28

90˚

5 93˚ 0.28 15

10

90˚

5

Fig. 1- Generated profile for a Fig. 2- Generated profile for a depth

depth of cut of up to 5mm of cut in stepdown milling

Starting feed per tooth Fz for S890 face mills with inserts S890 SZMU 08...

Workpiece Material Fz, mm/Tooth for Grades*

ISO Class Typical Representstive Hardness, ISCAR Mat.

DIN/ISO 513 Description AISI/SAE/ASTM DIN W.-Nr. HB Group** IC 5100 IC810 IC808 IC845 IC5400

Non-alloy steel 1020 1.044 130-180 1 0.1-0.25 0.1-0.25 0.1-0.25

4340 1.658 260-300 8 0.1-0.2 0.1-0.2 0.1-0.2

Alloy steel

P 4340 1.658 HRC 35-42* 9 0.1-0.2 0.1-0.2 0.1-0.2

High alloy steel H13 1.234 200-220 10 0.08-0.15 0.08-0.15 0.08-0.15

Martensitic s.s 420 1.402 200 12 0.08-0.15 0.08-0.15 0.08-0.15

304L 1.431 200 14 0.1-0.15 0.1-0.15 0.1-0.15

M Austenitic s.s.

316L 1.440 140 14 0.1-0.15 0.1-0.15 0.1-0.15

Grey cast iron Class 40 0.6025 (GG25) 250 16 0.15-0.25 0.15-0.25

K

Nodular cast iron Class 65-45-12 0.7050 (GGG50) 200 17 0.12-0.2 0.12-0.2

Hard steel and H11 1.234 HRC 45-49 38.1 0.06-0.12 0.06-0.12 0.06-0.12

H

cast iron P20 1.2330 HRC 50-55 38.2 0.05-0.1 0.05-0.1 0.05-0.1

* Quenched and tempered

** ISCAR material group in accordance with VDI 3323 standard

Spare Parts

Designation

S890 FSZ D040-05-16-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151 SR M8X25DIN912

S890 FSZ D040-06-16-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151 SR M8X25DIN912

S890 FSZ D050-06-22-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151 SR M10X25 DIN912

S890 FSZ D050-08-22-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151 SR M10X25 DIN912

S890 FSZ D063-07-22-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151 SR M10X25 DIN912

S890 FSZ D063-10-22-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151 SR M10X25 DIN912

S890 FSZ D080-08-27-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151

S890 FSZ D080-12-27-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151

S890 FSZ D100-10-32-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151

S890 FSZ D100-14-32-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151

S890 FSZ D125-12-40-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151

S890 FSZ D125-18-40-R08 SR M3X0.5-L7.4 IP9 (a) IP-9/151

(a) Recommended tightening torque:2 N*m (17.7 lbf*in)

194 ISCAR