Page 295 - ISCAR(MILLINGCATALOG 38_2021)

P. 295

OAL

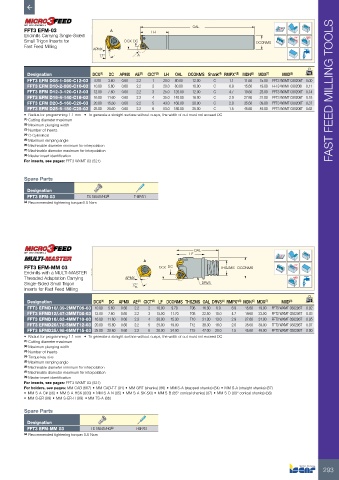

FFT3 EFM-03 A LH

Endmills Carrying Single-Sided Rd°

Small Trigon Inserts for DCX DC DCONMS

Fast Feed Milling

APMX

17° A

Designation DCX (1) DC APMX AE (2) CICT (3) LH OAL DCONMS Shank (4) RMPX° (5) MDN (6) MDX (7) MIID (8) kg

FFT3 EFM D08-1-080-C12-03 8.00 3.60 0.60 2.2 1 20.0 80.00 12.00 C 1.1 11.60 15.00 FFT3 WXMT 030206T 0.00

FFT3 EFM D10-2-080-C10-03 10.00 5.60 0.60 2.2 2 20.0 80.00 10.00 C 6.9 15.60 19.00 FFT3 WXMT 030206T 0.11

FFT3 EFM D12-3-120-C12-03 12.00 7.60 0.60 2.2 3 25.0 120.00 12.00 C 4.7 19.60 23.00 FFT3 WXMT 030206T 0.14 FAST FEED MILLING TOOLS

FFT3 EFM D16-4-140-C16-03 16.00 11.60 0.60 2.2 4 35.0 140.00 16.00 C 2.9 27.60 31.00 FFT3 WXMT 030206T 0.18

FFT3 EFM D20-5-160-C20-03 20.00 15.60 0.60 2.2 5 43.0 160.00 20.00 C 2.0 35.60 39.00 FFT3 WXMT 030206T 0.37

FFT3 EFM D25-6-180-C25-03 25.00 20.60 0.60 2.2 6 53.0 180.00 25.00 C 1.5 45.60 49.00 FFT3 WXMT 030206T 0.62

• Radius for programming 1.1 mm • To generate a straight surface without cusps, the width of cut must not exceed DC

(1) Cutting diameter maximum

(2) Maximum plunging width

(3) Number of inserts

(4) C-Cylindrical

(5) Maximum ramping angle

(6) Machinable diameter minimum for interpolation

(7) Machinable diameter maximum for interpolation

(8) Master insert identification

For inserts, see pages: FFT3 WXMT 03 (521)

Spare Parts

Designation

FFT3 EFM-03 TS 18041I/HG (a) T-6IP/51

(a) Recommended tightening torque:0.5 Nxm

OAL

LF

A

FFT3 EFM-MM 03 DCX DC THSZMS DCONMS Rd°

Endmills with a MULTI-MASTER

Threaded Adaptation Carrying APMX

Single-Sided Small Trigon 17° DRVS

Inserts for Fast Feed Milling

Designation DCX (1) DC APMX AE (2) CICT (3) LF DCONMS THSZMS OAL DRVS (4) RMPX° (5) MDN (6) MDX (7) MIID (8) kg

FFT3 EFMD10/.39-2MMT06-03 10.00 5.60 0.60 2.2 2 10.00 9.70 T06 16.30 8.0 6.9 15.60 19.00 FFT3 WXMT 030206T 0.02

FFT3 EFMD12/.47-3MMT08-03 12.00 7.60 0.60 2.2 3 15.00 11.70 T08 22.50 10.0 4.7 19.60 23.00 FFT3 WXMT 030206T 0.03

FFT3 EFMD16/.63-4MMT10-03 16.00 11.60 0.60 2.2 4 20.00 15.30 T10 31.30 13.0 2.9 27.60 31.00 FFT3 WXMT 030206T 0.05

FFT3 EFMD20/.78-5MMT12-03 20.00 15.60 0.60 2.2 5 25.00 19.00 T12 38.30 16.0 2.0 35.60 39.00 FFT3 WXMT 030206T 0.07

FFT3 EFMD25/.98-6MMT15-03 25.00 20.60 0.60 2.2 6 30.00 24.00 T15 47.00 20.0 1.5 45.60 49.00 FFT3 WXMT 030206T 0.00

• Radius for programming 1.1 mm • To generate a straight surface without cusps, the width of cut must not exceed DC

(1) Cutting diameter maximum

(2) Maximum plunging width

(3) Number of inserts

(4) Torque key size

(5) Maximum ramping angle

(6) Machinable diameter minimum for interpolation

(7) Machinable diameter maximum for interpolation

(8) Master insert identification

For inserts, see pages: FFT3 WXMT 03 (521)

For holders, see pages: MM CAB (667) • MM CAB-T-T (91) • MM GRT (shanks) (86) • MM S-A (stepped shanks) (84) • MM S-A (straight shanks) (87)

• MM S-A-C# (86) • MM S-A-HSK (609) • MM S-A-N (85) • MM S-A-SK (90) • MM S-B (85° conical shanks) (87) • MM S-D (89° conical shanks) (88)

• MM S-ER (89) • MM S-ER-H (89) • MM TS-A (86)

Spare Parts

Designation

FFT3 EFM-MM 03 TS 18041I/HG (a) T-6IP/51

(a) Recommended tightening torque: 0.5 Nxm

293