Page 310 - ISCAR(MILLINGCATALOG 38_2021)

P. 310

FAST FEED MILLING TOOLS

DHUB

DCONMS

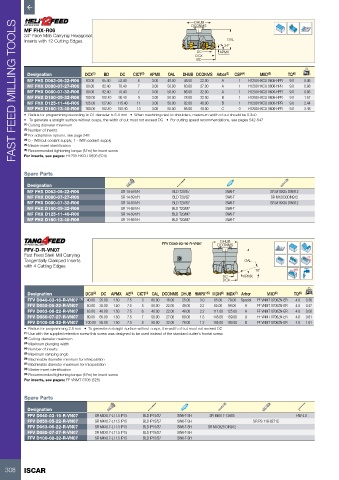

MF FHX-R06

34° Face Mills Carrying Hexagonal

Inserts with 12 Cutting Edges OAL

34°

DC APMX

DCX

BD

Designation DCX (1) BD DC CICT (2) APMX OAL DHUB DCONMS Arbor (3) CSP (4) MIID (5) TQ (6) kg

MF FHX D063-06-22-R06 63.00 65.40 53.40 6 3.00 40.00 48.00 22.00 A 1 H1200 HXCU 0606-HPR 9.0 0.46

MF FHX D080-07-27-R06 80.00 82.40 70.40 7 3.00 50.00 60.00 27.00 A 1 H1200 HXCU 0606-HPR 9.0 0.98

MF FHX D080-07-32-R06 80.00 82.40 70.40 7 3.00 50.00 66.00 32.00 A 1 H1200 HXCU 0606-HPR 9.0 0.86

MF FHX D100-09-32-R06 100.00 102.40 90.40 9 3.00 50.00 78.00 32.00 B 1 H1200 HXCU 0606-HPR 9.0 1.57

MF FHX D125-11-40-R06 125.00 127.40 115.40 11 3.00 50.00 92.00 40.00 B 1 H1200 HXCU 0606-HPR 9.0 2.44

MF FHX D160-13-40-R06 160.00 162.40 150.40 13 3.00 55.00 95.00 40.00 C 0 H1200 HXCU 0606-HPR 9.0 3.48

• Radius for programming according to D1 diameter is 5.4 mm • When machining next to shoulders, maximum width of cut should be 0.3xD

• To generate a straight surface without cusps, the width of cut must not exceed DC • For cutting speed recommendations, see pages 542-547

(1) Cutting diameter maximum

(2) Number of inserts

(3) For adaptation options, see page 548

(4) 0 - Without coolant supply, 1 - With coolant supply

(5) Master insert identification

(6) Recommended tightening torque (N*m) for insert screw

For inserts, see pages: H1200 HXCU 0606 (524)

Spare Parts

Designation

MF FHX D063-06-22-R06 SR 14-591/H BLD T20/S7 SW6-T SR M10X25 DIN912

MF FHX D080-07-27-R06 SR 14-591/H BLD T20/S7 SW6-T SR M12X30DIN912

MF FHX D080-07-32-R06 SR 14-591/H BLD T20/S7 SW6-T SR M16X30 DIN912

MF FHX D100-09-32-R06 SR 14-591/H BLD T20/M7 SW6-T

MF FHX D125-11-40-R06 SR 14-591/H BLD T20/M7 SW6-T

MF FHX D160-13-40-R06 SR 14-591/H BLD T20/M7 SW6-T

DHUB

FFV D040-03-16-R-VN07

DCONMS

FFV-D-R-VN07

Fast Feed Shell Mill Carrying Rd°

Tangentially Clamped Inserts OAL

with 4 Cutting Edges

16˚

DC APMX

DCX

Designation DCX (2) DC APMX AE (3) CICT (4) OAL DCONMS DHUB RMPX° (5) MDN (6) MDX (7) Arbor MIID (8) TQ (9) kg

FFV D040-03-16-R-VN07 (1) 40.00 25.00 1.50 7.5 3 60.00 16.00 25.00 3.0 65.00 79.00 Special FF VNMT 0706ZN-ER 4.8 0.36

FFV D050-05-22-R-VN07 50.00 35.00 1.50 7.5 5 50.00 22.00 48.00 3.2 85.00 99.00 A FF VNMT 0706ZN-ER 4.8 0.47

FFV D063-06-22-R-VN07 63.00 48.00 1.50 7.5 6 40.00 22.00 48.00 2.2 111.00 125.00 A FF VNMT 0706ZN-ER 4.8 0.00

FFV D080-07-27-R-VN07 80.00 65.00 1.50 7.5 7 50.00 27.00 60.00 1.5 145.00 159.00 B FF VNMT 0706ZN-ER 4.8 0.81

FFV D100-08-32-R-VN07 100.00 85.00 1.50 7.5 8 50.00 32.00 78.00 1.2 185.00 199.00 B FF VNMT 0706ZN-ER 4.8 1.61

• Radius for programming 2.8 mm • To generate a straight surface without cusps, the width of cut must not exceed DC

(1) Use with the supplied retention screw this screw was designed to be used instead of the standard cutter's frontal screw

(2) Cutting diameter maximum

(3) Maximum plunging width

(4) Number of inserts

(5) Maximum ramping angle

(6) Machinable diameter minimum for interpolation

(7) Machinable diameter maximum for interpolation

(8) Master insert identification

(9) Recommended tightening torque (N*m) for insert screw

For inserts, see pages: FF VNMT 0706 (525)

Spare Parts

Designation

FFV D040-03-16-R-VN07 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR M8X17-13685 HW 4.0

FFV D050-05-22-R-VN07 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR PS 118-0271C

FFV D063-06-22-R-VN07 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR M10X25 DIN912

FFV D080-07-27-R-VN07 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH

FFV D100-08-32-R-VN07 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH

308 ISCAR