Page 306 - ISCAR(MILLINGCATALOG 38_2021)

P. 306

FAST FEED MILLING TOOLS

DHUB

DCONMS

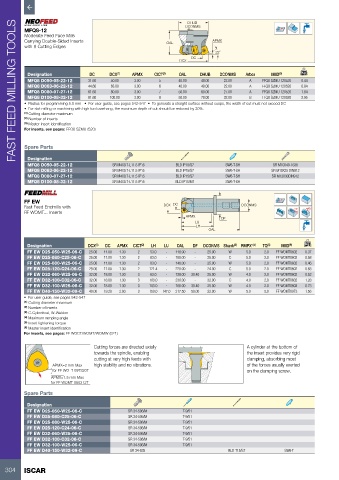

MFQ8-12

Moderate Feed Face Mills

Carrying Double-Sided Inserts OAL APMX

with 8 Cutting Edges

22˚

DC

DCX

Designation DC DCX (1) APMX CICT (2) OAL DHUB DCONMS Arbor MIID (3) kg

MFQ8 D050-05-22-12 31.60 50.00 3.00 5 40.00 48.00 22.00 A FFQ8 SZMU 120520 0.44

MFQ8 D063-06-22-12 44.60 63.00 3.00 6 40.00 48.00 22.00 A FFQ8 SZMU 120520 0.84

MFQ8 D080-07-27-12 61.60 80.00 3.00 7 50.00 60.00 27.00 A FFQ8 SZMU 120520 1.84

MFQ8 D100-08-32-12 81.60 100.00 3.00 8 50.00 78.00 32.00 B FFQ8 SZMU 120520 2.95

• Radius for programming 5.0 mm • For user guide, see pages 542-547 • To generate a straight surface without cusps, the width of cut must not exceed DC

• For slot milling or machining with high tool overhang, the maximum depth of cut should be reduced by 30%.

(1) Cutting diameter maximum

(2) Number of inserts

(3) Master insert identification

For inserts, see pages: FFQ8 SZMU (520)

Spare Parts

Designation

MFQ8 D050-05-22-12 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR M10X40-1638

MFQ8 D063-06-22-12 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR M10X25 DIN912

MFQ8 D080-07-27-12 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR M12X30DIN912

MFQ8 D100-08-32-12 SR M4X0.7-L11.5 IP15 BLD IP15/M7 SW6-T-SH

FF EW DC

Fast Feed Endmills with DCX DCONMS Rd°

FF WOMT... Inserts

APMX

DF

LU

LH

OAL

Designation DCX (1) DC APMX CICT (2) LH LU OAL DF DCONMS Shank (3) RMPX° (4) TQ (5) MIID (6) kg

FF EW D25-050-W25-06-C 25.00 11.00 1.30 2 53.0 - 118.00 - 25.00 W 5.0 2.0 FF WOMT0602 0.37

FF EW D25-080-C25-06-C 25.00 11.00 1.30 2 83.0 - 180.00 - 25.00 C 5.0 2.0 FF WOMT0602 0.58

FF EW D25-080-W25-06-C 25.00 11.00 1.30 2 83.0 - 148.00 - 25.00 W 5.0 2.0 FF WOMT0602 0.46

FF EW D25-120-C24-06-C 25.00 11.00 1.30 2 121.4 - 220.00 - 24.00 C 5.0 2.0 FF WOMT0602 0.68

FF EW D32-060-W25-06-C 32.00 18.00 1.30 3 63.0 - 128.00 30.40 25.00 W 4.0 2.0 FF WOMT0602 0.52

FF EW D32-100-C32-06-C 32.00 18.00 1.30 3 103.0 - 230.00 - 32.00 C 4.0 2.0 FF WOMT0602 1.28

FF EW D32-100-W25-06-C 32.00 18.00 1.30 3 103.0 - 168.00 30.40 25.00 W 4.0 2.0 FF WOMT0602 0.73

FF EW D40-150-W32-09-C 40.00 19.20 2.00 3 150.0 147.0 217.50 50.00 32.00 W 5.0 5.0 FF WOMT09T3 1.56

• For user guide, see pages 542-547

(1) Cutting diameter maximum

(2) Number of inserts

(3) C-Cylindrical, W-Weldon

(4) Maximum ramping angle

(5) Insert tightening torque

(6) Master insert identification

For inserts, see pages: FF WOCT/WOMT/WOMW (521)

Cutting forces are directed axially A cylinder at the bottom of

towards the spindle, enabling the insert provides very rigid

cutting at very high feeds with clamping, absorbing most

APMX=2 mm Max high stability and no vibrations. of the forces usually exerted

for FF WO_T 09T320T on the clamping screw.

APMX=1.5 mm Max

for FF WOMT 060212T

Spare Parts

Designation

FF EW D25-050-W25-06-C SR 34-506/M T-9/51

FF EW D25-080-C25-06-C SR 34-506/M T-9/51

FF EW D25-080-W25-06-C SR 34-506/M T-9/51

FF EW D25-120-C24-06-C SR 34-506/M T-9/51

FF EW D32-060-W25-06-C SR 34-506/M T-9/51

FF EW D32-100-C32-06-C SR 34-506/M T-9/51

FF EW D32-100-W25-06-C SR 34-506/M T-9/51

FF EW D40-150-W32-09-C SR 34-535 BLD T15/S7 SW6-T

304 ISCAR