Page 325 - ISCAR(MILLINGCATALOG 38_2021)

P. 325

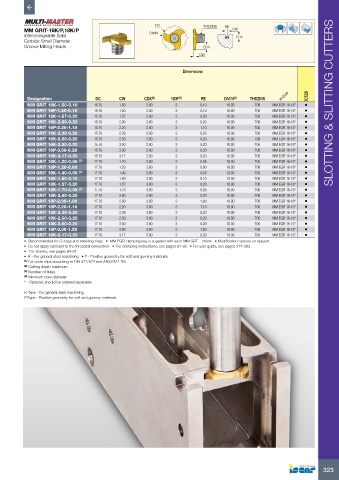

DC

THSZMS RE

MM GRIT-16K/P,18K/P CW

Interchangeable Solid DMIN CDX

Carbide Small Diameter

Groove Milling Heads CDX

CW

Dimensions

IC528

Designation DC CW CDX (2) NOF (3) RE DMIN (4) THSZMS

MM GRIT 16K-1.50-0.10 15.70 1.50 2.80 3 0.10 16.00 T06 MM EGR 16-18* • SLOTTING & SLITTING CUTTERS

MM GRIT 16P-1.50-0.10 15.70 1.50 2.80 3 0.10 16.00 T06 MM EGR 16-18* •

MM GRIT 16K-1.57-0.20 15.70 1.57 2.80 3 0.20 16.00 T06 MM EGR 16-18* •

MM GRIT 16K-2.00-0.20 15.70 2.00 2.80 3 0.20 16.00 T06 MM EGR 16-18* •

MM GRIT 16P-2.20-1.10 15.70 2.20 2.80 3 1.10 16.00 T06 MM EGR 16-18* •

MM GRIT 16K-2.39-0.20 15.70 2.39 2.80 3 0.20 16.00 T06 MM EGR 16-18* •

MM GRIT 16K-2.50-0.20 15.70 2.50 2.80 3 0.20 16.00 T06 MM EGR 16-18* •

MM GRIT 16K-3.00-0.20 15.70 3.00 2.80 3 0.20 16.00 T06 MM EGR 16-18* •

MM GRIT 16P-3.00-0.20 15.70 3.00 2.80 3 0.20 16.00 T06 MM EGR 16-18* •

MM GRIT 16K-3.17-0.20 15.70 3.17 2.80 3 0.20 16.00 T06 MM EGR 16-18* •

MM GRIT 18K-1.20-0.05 (1) 17.70 1.20 3.80 3 0.05 18.00 T06 MM EGR 16-18* •

MM GRIT 18P-1.20-0.60 17.70 1.20 3.80 3 0.60 18.00 T06 MM EGR 16-18* •

MM GRIT 18K-1.40-0.05 (1) 17.70 1.40 3.80 3 0.05 18.00 T06 MM EGR 16-18* •

MM GRIT 18K-1.50-0.10 17.70 1.50 3.80 3 0.10 18.00 T06 MM EGR 16-18* •

MM GRIT 18K-1.57-0.20 17.70 1.57 3.80 3 0.20 18.00 T06 MM EGR 16-18* •

MM GRIT 18K-1.70-0.05 (1) 17.70 1.70 3.80 3 0.05 18.00 T06 MM EGR 16-18* •

MM GRIT 18K-2.00-0.20 17.70 2.00 3.80 3 0.20 18.00 T06 MM EGR 16-18* •

MM GRIT 18P-2.00-1.00 17.70 2.00 3.80 3 1.00 18.00 T06 MM EGR 16-18* •

MM GRIT 18P-2.20-1.10 17.70 2.20 3.80 3 1.10 18.00 T06 MM EGR 16-18* •

MM GRIT 18K-2.39-0.20 17.70 2.39 3.80 3 0.20 18.00 T06 MM EGR 16-18* •

MM GRIT 18K-2.50-0.20 17.70 2.50 3.80 3 0.20 18.00 T06 MM EGR 16-18* •

MM GRIT 18K-3.00-0.20 17.70 3.00 3.80 3 0.20 18.00 T06 MM EGR 16-18* •

MM GRIT 18P-3.00-1.50 17.70 3.00 3.80 3 1.50 18.00 T06 MM EGR 16-18* •

MM GRIT 18K-3.17-0.20 17.70 3.17 3.80 3 0.20 18.00 T06 MM EGR 16-18* •

• Recommended for O-rings and retaining rings • MM EGR clamping key is supplied with each MM GRT... shank • Modification options on request

• Do not apply lubricant to the threaded connection • For clamping instructions, see pages 91-92 • For user guide, see pages 377-383

• For shanks, see pages 84-91

• K - For general steel machining • P - Positive geometry for soft and gummy materials

(1) For circle clips according to DIN 471/472 and ANSI B27.7M

(2) Cutting depth maximum

(3) Number of flutes

(4) Minimum bore diameter

* Optional, should be ordered separately

K-Type - For general steel machining.

P-Type - Positive geometry for soft and gummy materials.

323