Page 328 - ISCAR(MILLINGCATALOG 38_2021)

P. 328

SLOTTING & SLITTING CUTTERS

CW≤1.2

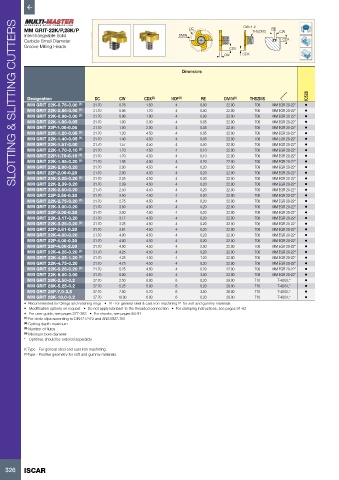

MM GRIT-22K/P,28K/P DC THSZMS RE CW

Interchangeable Solid DMIN

Carbide Small Diameter CDX

Groove Milling Heads

CDX

CW CDX

Dimensions

IC528

Designation DC CW CDX (2) NOF (3) RE DMIN (4) THSZMS

MM GRIT 22K-0.76-0.00 (1) 21.70 0.76 1.50 4 0.00 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-0.86-0.00 (1) 21.70 0.86 1.70 4 0.00 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-0.96-0.00 (1) 21.70 0.96 1.90 4 0.00 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.00-0.05 21.70 1.00 2.00 4 0.05 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-1.00-0.05 21.70 1.00 2.00 4 0.05 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.20-0.05 (1) 21.70 1.20 4.50 4 0.05 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.40-0.05 (1) 21.70 1.40 4.50 4 0.05 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.57-0.00 21.70 1.57 4.50 4 0.00 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.70-0.10 (1) 21.70 1.70 4.50 4 0.10 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-1.70-0.10 (1) 21.70 1.70 4.50 4 0.10 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.95-0.20 (1) 21.70 1.95 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-2.00-0.20 21.70 2.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-2.00-0.20 21.70 2.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-2.25-0.20 (1) 21.70 2.25 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-2.39-0.20 21.70 2.39 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-2.50-0.20 21.70 2.50 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-2.50-0.20 21.70 2.50 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-2.75-0.20 (1) 21.70 2.75 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-3.00-0.20 21.70 3.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-3.00-0.20 21.70 3.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-3.17-0.20 21.70 3.17 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-3.25-0.20 (1) 21.70 3.25 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-3.81-0.20 21.70 3.81 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-4.00-0.20 21.70 4.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-4.00-0.20 21.70 4.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-4.00-2.00 21.70 4.00 4.50 4 2.00 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-4.25-0.20 (1) 21.70 4.25 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-4.25-1.20 (1) 21.70 4.25 4.50 4 1.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-4.75-0.20 21.70 4.75 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-5.25-0.20 (1) 21.70 5.25 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-6.00-3.00 21.70 6.00 4.50 4 3.00 22.00 T08 MM EGR 20-22* •

MM GRIT 28K-2.50-0.2 27.70 2.50 6.00 6 0.20 28.00 T10 T-40/3 L* •

MM GRIT 28K-5.25-0.2 27.70 5.25 6.00 6 0.20 28.00 T10 T-40/3 L* •

MM GRIT 28P-7.0-3.5 27.70 7.00 5.70 6 3.50 28.00 T10 T-40/3 L* •

MM GRIT 28K-10.0-0.2 27.70 10.00 6.00 6 0.20 28.00 T10 T-40/3 L* •

• Recommended for O rings and retaining rings • K - for general steel & cast iron machining P for soft and gummy materials

• Modification options on request • Do not apply lubricant to the threaded connection • For clamping instructions, see pages 91-92

• For user guide, see pages 377-383 • For shanks, see pages 84-91

(1) For circle clips according to DIN471/472 and ANSI B27.7M

(2) Cutting depth maximum

(3) Number of flutes

(4) Minimum bore diameter

* Optional, should be ordered separately

K-Type - For general steel and cast iron machining.

P-Type - Positive geometry for soft and gummy materials.

326 ISCAR