Page 331 - ISCAR(MILLINGCATALOG 38_2021)

P. 331

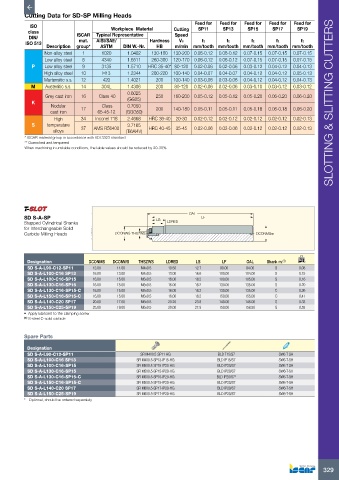

Cutting Data for SD-SP Milling Heads

Feed for Feed for Feed for Feed for Feed for

ISO Workpiece Material SP11 SP13 SP15 SP17 SP19

class ISCAR Typical Representative Cutting

Speed

DIN/

ISO 513 mat. AISI/SAE/ Hardness Vc fz fz fz fz fz

Description group* ASTM DIN W.-Nr. HB m/min mm/tooth mm/tooth mm/tooth mm/tooth mm/tooth

Non-alloy steel 1 1020 1.0402 130-180 130-200 0.06-0.12 0.06-0.12 0.07-0.15 0.07-0.15 0.07-0.15

Low alloy steel 8 4340 1.6511 260-300 120-170 0.06-0.12 0.06-0.12 0.07-0.15 0.07-0.15 0.07-0.15

P Low alloy steel 9 3135 1.5710 HRC 35-40* 80-120 0.02-0.06 0.02-0.06 0.03-0.12 0.04-0.12 0.04-0.13

High alloy steel 10 H13 1.2344 200-220 100-140 0.04-0.07 0.04-0.07 0.04-0.12 0.04-0.12 0.05-0.13

Martensitic s.s. 12 420 1.4021 200 100-140 0.03-0.06 0.03-0.06 0.04-0.12 0.04-0.12 0.04-0.13

M Austenitic s.s. 14 304L 1.4306 200 80-120 0.02-0.06 0.02-0.06 0.03-0.10 0.03-0.12 0.03-0.12

0.6025

Grey cast iron 16 Class 40 250 160-200 0.05-0.12 0.05-0.12 0.05-0.20 0.06-0.20 0.06-0.20

K (GG25) SLOTTING & SLITTING CUTTERS

Nodular Class 0.7050

cast iron 17 65-45-12 (GGG50) 200 140-180 0.05-0.11 0.05-0.11 0.05-0.18 0.06-0.18 0.06-0.20

High 34 Inconel 718 2.4668 HRC 36-40 20-30 0.02-0.12 0.02-0.12 0.02-0.12 0.02-0.12 0.02-0.13

S temperature 3.7165

alloys 37 AMS R56400 (Ti6Al4V) HRC 40-45 35-45 0.02-0.06 0.02-0.06 0.02-0.12 0.02-0.12 0.02-0.13

* ISCAR material group in accordance with VDI 3323 standard

** Quenched and tempered

When machining in unstable conditions, the table values should be reduced by 20-30%.

OAL

SD S-A-SP LB LF

Stepped Cylindrical Shanks LDRED

for Interchangeable Solid

Carbide Milling Heads DCONWS THSZWS DCONMSh6

Designation DCONMS DCONWS THSZWS LDRED LB LF OAL Shank m. (1) kg

SD S-A-L90-C12-SP11 12.00 11.00 M4x0.5 10.50 12.7 90.00 94.00 S 0.08

SD S-A-L100-C16 SP13 16.00 13.00 M4x0.5 13.00 16.6 100.00 104.00 S 0.15

SD S-A-L100-C16-SP15 16.00 15.00 M5x0.5 16.00 18.2 100.00 105.00 S 0.16

SD S-A-L130-C16-SP15 16.00 15.00 M5x0.5 16.00 18.2 130.00 135.00 S 0.20

SD S-A-L130-C16-SP15-C 16.00 15.00 M5x0.5 16.00 18.2 130.00 135.00 C 0.36

SD S-A-L150-C16-SP15-C 16.00 15.00 M5x0.5 16.00 18.2 150.00 155.00 C 0.41

SD S-A-L140-C20 SP17 20.00 17.00 M6x0.5 20.20 23.8 140.00 146.00 S 0.33

SD S-A-L150-C25-SP19 25.00 19.00 M6x0.5 20.00 27.9 150.00 158.50 S 0.55

• Apply lubricant to the clamping screw

(1) S-steel C-solid carbide

Spare Parts

Designation

SD S-A-L90-C12-SP11 SR M4X0.5-SP11 HG BLD T15/S7 SW6-T-SH

SD S-A-L100-C16 SP13 SR M4X0.5-SP13-IP15-HG BLD IP15/S7 SW6-T-SH

SD S-A-L100-C16-SP15 SR M5X0.5-SP15-IP20-HG BLD IP20/S7 SW6-T-SH

SD S-A-L130-C16-SP15 SR M5X0.5-SP15-IP20-HG BLD IP20/S7 SW6-T-SH

SD S-A-L130-C16-SP15-C SR M5X0.5-SP15-IP20-HG BLD IP20/S7* SW6-T-SH

SD S-A-L150-C16-SP15-C SR M5X0.5-SP15-IP20-HG BLD IP20/S7 SW6-T-SH

SD S-A-L140-C20 SP17 SR M6X0.5-SP17-IP20-HG BLD IP20/S7 SW6-T-SH

SD S-A-L150-C25-SP19 SR M6X0.5-SP17-IP20-HG BLD IP20/S7 SW6-T-SH

* Optional, should be ordered separately

329