Page 380 - ISCAR(MILLINGCATALOG 38_2021)

P. 380

USER GUIDE

SLOTTING & SLITTING CUTTERS

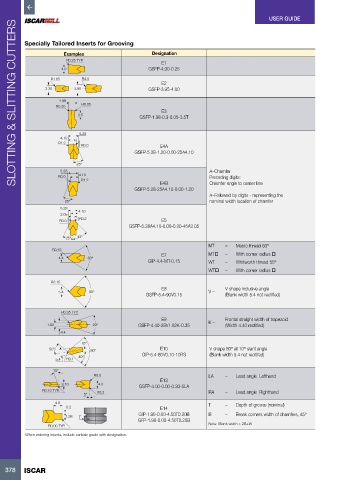

Specially Tailored Inserts for Grooving

Examples Designation

R0.25 TYP.

E1

4.0 GSFP-4.00-0.25

R1.65 R4.0

E2

3.30 3.95 GSFP-3.95-4.00

1.98

R0.30 R0.05

E3

3.5 GSFP-1.98-0.3-0.05-3.5T

5.28

4.10

R1.2

R0.0 E4A

GSFP-5.28-1.20-0.00-25A4.10

25°

5.28 A–Chamfer

R0.0 4.10 Preceding digits:

R1.2

E4B Chamfer angle to center line

GSFP-5.28-25A4.10-0.00-1.20

A–Followed by digits - representing the

25° nominal width location of chamfer

5.28

4.10

2.05

R0.0 R0.2 E5

GSFP-5.28A4.10-0.00-0.20-45A2.05

25° 45°

MT – Metric thread 60º

R0.15

E7 MT – With corner radius

4.4 60°

GIP-4.4-MT-0.15 WT – Whitworth thread 55º

WT – With corner radius

R0.15

E8 V shape inclusive angle

5.4 90° V –

GSFP-5.4-90V0.15 (Blank width 5.4 not rectified)

R0.35 TYP.

E9 K – Frontal straight width of trapezoid

1.82 29° GSFP-4.40-29V1.82K-0.35 (Width 4.40 rectified)

4.4

10°

50° 80° E10 V shape 80º at 10º slant angle

40° GIP-5.4-80V0.10-10RS (Blank width 5.4 not recitifed)

5.4 R0.1

15°

R0.0 LA – Lead angle Lefthand

E13

3.10 4.0 GSFP-4.00-0.00-0.30-5LA

R0.10 TYP. R0.3 RA – Lead angle Righthand

5°

4.5 T – Depth of groove (nominal)

0.2 E14

GIP-1.98-0.00-4.50T0.20B B – Break corners width of chamfers, 45º

1.98 T

GFP-1.98-0.00-4.50T0.20B

R0.00 TYP. Note: Blank width > 2B+W

When ordering inserts, include carbide grade with designation.

378 ISCAR