Page 47 - ISCAR(MILLINGCATALOG 38_2021)

P. 47

THSZMS

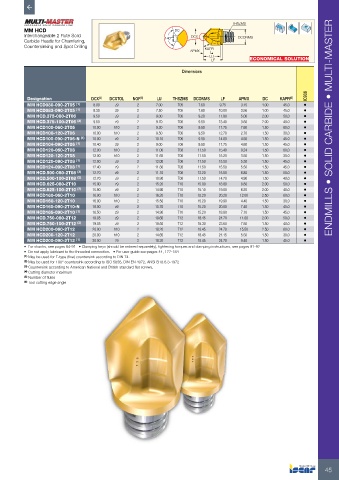

MM HCD DC

Interchangeable 2 Flute Solid 140° DCX DCONMS

Carbide Heads for Chamfering,

Countersinking and Spot Drilling

APMX KAPR

LU

LF ECONOMICAL SOLUTION

Dimensions

IC908

Designation DCX (4) DCXTOL NOF (5) LU THSZMS DCONMS LF APMX DC KAPR (6)

MM HCD080-090-2T05 (1) 8.00 z9 2 7.00 T05 7.60 9.75 3.15 1.00 45.0 •

MM HCD083-090-2T05 (1) 8.30 z9 2 7.50 T05 7.60 10.00 3.56 1.00 45.0 •

MM HCD.375-080-2T06 9.50 z9 2 9.00 T06 9.20 11.80 5.00 2.00 50.0 •

MM HCD.375-100-2T06 (2) 9.50 z9 2 9.70 T06 9.50 13.40 3.60 2.00 40.0 •

MM HCD100-060-2T06 10.00 h10 2 9.30 T06 9.50 11.75 7.60 1.50 60.0 • ENDMILLS • SOLID CARBIDE • MULTI-MASTER

MM HCD100-120-2T06 10.00 h10 2 9.50 T06 9.50 12.70 2.70 1.50 30.0 •

MM HCD100-090-2T06-N (1) 10.00 z9 2 10.10 T06 9.50 14.00 4.50 1.50 45.0 •

MM HCD104-090-2T06 (1) 10.40 z9 2 9.00 T06 9.50 11.75 4.60 1.50 45.0 •

MM HCD120-060-2T08 12.00 h10 2 11.00 T08 11.50 15.40 9.24 1.50 60.0 •

MM HCD120-120-2T08 12.00 h10 2 11.65 T08 11.50 15.20 3.50 1.50 30.0 •

MM HCD120-090-2T08 (1) 12.00 z9 2 12.00 T08 11.50 15.50 5.30 1.50 45.0 •

MM HCD124-090-2T08 (1) 12.40 z9 2 11.80 T08 11.50 15.50 5.50 1.50 45.0 •

MM HCD.500-080-2T08 (3) 12.70 z9 2 11.10 T08 12.20 15.50 6.80 1.50 50.0 •

MM HCD.500-100-2T08 (2) 12.70 z9 2 10.90 T08 11.50 14.70 4.90 1.50 40.0 •

MM HCD.625-080-2T10 15.90 z9 2 15.20 T10 15.00 18.80 8.80 2.00 50.0 •

MM HCD.625-100-2T10 (2) 15.90 z9 2 14.90 T10 15.10 19.00 6.20 2.00 40.0 •

MM HCD160-060-2T10 16.00 h10 2 16.20 T10 15.20 20.20 12.00 2.50 60.0 •

MM HCD160-120-2T10 16.00 h10 2 15.50 T10 15.20 19.90 4.40 1.50 30.0 •

MM HCD160-090-2T10-N 16.00 z9 2 15.70 T10 15.20 20.00 7.40 1.50 45.0 •

MM HCD165-090-2T10 (1) 16.50 z9 2 14.90 T10 15.20 18.80 7.10 1.50 45.0 •

MM HCD.750-080-2T12 19.05 z9 2 19.60 T12 18.45 24.70 11.00 2.00 50.0 •

MM HCD.750-100-2T12 (2) 19.05 z9 2 18.50 T12 18.30 23.60 7.50 1.50 40.0 •

MM HCD200-060-2T12 20.00 h10 2 18.20 T12 18.45 24.70 15.50 2.50 60.0 •

MM HCD200-120-2T12 20.00 h10 2 14.65 T12 18.45 21.15 5.50 1.50 30.0 •

MM HCD200-090-2T12 (1) 20.00 z9 2 18.20 T12 18.45 24.70 9.40 1.50 45.0 •

• For shanks, see pages 84-91 • Clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 91-92

• Do not apply lubricant to the threaded connection. • For user guide see pages 44, 177-184

(1) May be used for F-type (fine) countersink according to DIN 74.

(2) May be used for 100° countersink according to ISO 5856, DIN EN 4072, ANSI B18.6.3-1972

(3) Countersink according to American National and British standard flat screws.

(4) Cutting diameter maximum

(5) Number of flutes

(6) Tool cutting edge angle

45