Page 479 - ISCAR(MILLINGCATALOG 38_2021)

P. 479

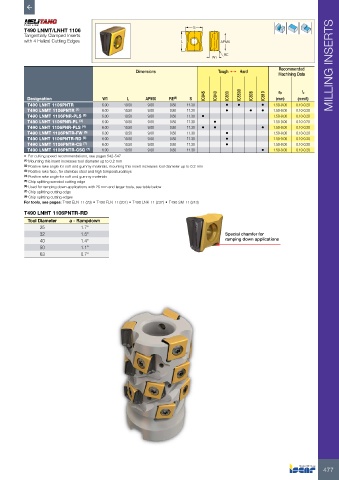

T490 LNMT/LNHT 1106 S

Tangentially Clamped Inserts

with 4 Helical Cutting Edges L APMX

RE

W1

Dimensions Tough 1 Hard Recommended MILLING INSERTS

Machining Data

IC845 IC840 IC830 IC5500 IC808 IC810 ap fz

Designation W1 L APMX RE (8) S (mm) (mm/t)

T490 LNHT 1106PNTR 6.00 10.50 9.00 0.80 11.30 • • • 1.50-9.00 0.10-0.20

T490 LNMT 1106PNTR (1) 6.00 10.50 9.00 0.80 11.30 • • • 1.50-9.00 0.10-0.20

T490 LNMT 1106PNR-PLS (2) 6.00 10.50 9.00 0.80 11.30 • 1.50-9.00 0.10-0.20

T490 LNHT 1106PNR-PL (3) 6.00 10.50 9.00 0.80 11.30 • 1.50-9.00 0.10-0.20

T490 LNHT 1106PNR-PLS (4) 6.00 10.50 9.00 0.80 11.30 • • • 1.50-9.00 0.10-0.20

T490 LNMT 1106PNTR-FW (5) 6.00 10.50 9.00 0.80 11.30 • 1.50-9.00 0.10-0.20

T490 LNHT 1106PNTR-RD (6) 6.00 10.50 9.00 0.80 11.30 • 1.50-9.00 0.10-0.20

T490 LNMT 1106PNTR-CS (7) 6.00 10.50 9.00 0.80 11.30 • 1.50-9.00 0.10-0.20

T490 LNMT 1106PNTR-CSG (7) 6.00 10.50 9.00 0.80 11.30 • 1.50-9.00 0.10-0.20

• For cutting speed recommendations, see pages 542-547

(1) Mounting this insert increases tool diameter up to 0.2 mm

(2) Positive rake angle for soft and gummy materials, mounting this insert increases tool diameter up to 0.2 mm

(3) Positive rake face, for stainless steel and high temperaturealloys

(4) Positive rake angle for soft and gummy materials

(5) Chip splitting serrated cutting edge

(6) Used for ramping down applications with 25 mm and larger tools, see table below

(7) Chip splitting cutting edge

(8) Chip splitting cutting edges

For tools, see pages: T490 ELN-11 (29) • T490 FLN-11 (201) • T490 LNK-11 (237) • T490 SM-11 (243)

T490 LNHT 1106PNTR-RD

Tool Diameter a - Rampdown

25 1.7°

32 1.5° Special chamfer for

40 1.4° ramping down applications

50 1.1°

63 0.7°

477