Page 481 - ISCAR(MILLINGCATALOG 38_2021)

P. 481

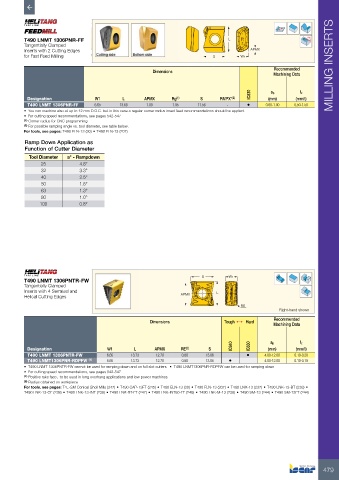

T490 LNMT 1306PNR-FF L Rd°

Tangentially Clamped

Inserts with 2 Cutting Edges APMX

for Fast Feed Milling S W1

Dimensions Recommended MILLING INSERTS

Machining Data

IC830 ap fz

Designation W1 L APMX Rg (1) S RMPX° (2) (mm) (mm/t)

T490 LNMT 1306PNR-FF 6.65 13.68 1.00 1.95 11.56 - • 0.60-1.00 0.50-1.50

• You can machine also at up to 12 mm D.O.C. but in this case a regular corner radius insert feed recommendations should be applied.

• For cutting speed recommendations, see pages 542-547

(1) Corner radius for CNC programming

(2) For possible ramping angle vs. tool diameter, see table below.

For tools, see pages: T490 ELN-13 (30) • T490 FLN-13 (207)

Ramp Down Application as

Function of Cutter Diameter

Tool Diameter a° - Rampdown

25 4.8°

32 3.3°

40 2.5°

50 1.8°

63 1.3°

80 1.0°

100 0.8°

T490 LNMT 1306PNTR-FW S W1

Tangentially Clamped

Inserts with 4 Serrated and L

Helical Cutting Edges APMX

RE

Right-hand shown

Recommended

Dimensions Tough 1 Hard

Machining Data

IC840 IC830 ap fz

Designation W1 L APMX RE (2) S (mm) (mm/t)

T490 LNMT 1306PNTR-FW 6.65 13.73 12.70 0.80 13.06 • 4.00-12.00 0.10-0.20

T490 LNMT1306PNR-RDPFW (1) 6.65 13.73 12.70 0.80 13.06 • 4.00-12.00 0.10-0.18

• T490 LNMT 1306PNTR-FW cannot be used for ramping down and on full slot cutters • T490 LNMT1306PNR-RDPFW can be used for ramping down

• For cutting speed recommendations, see pages 542-547

(1) Positive rake face, to be used in long overhang applications and low power machines

(2) Radius obtained on workpiece

For tools, see pages: T4..-SM Conical Shell Mills (247) • T490 CAP-13FT (245) • T490 ELN-13 (30) • T490 FLN-13 (207) • T490 LNK-13 (237) • T490 LNK-13-BT (238) •

T490 LNK-13-CF (238) • T490 LNK-13-INT (238) • T490 LNK-BT-FT (247) • T490 LNK-INT50-FT (246) • T490 LNK-M-13 (238) • T490 SM-13 (244) • T490 SM-13FT (244)

479