Page 483 - ISCAR(MILLINGCATALOG 38_2021)

P. 483

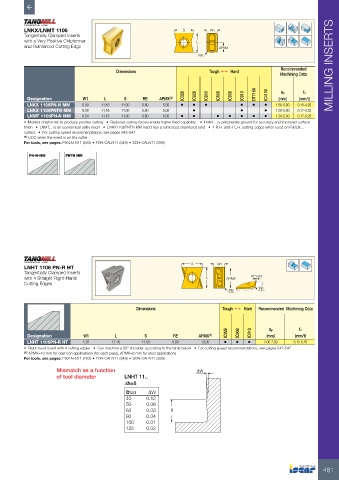

LNKX/LNMT 1106 S W1

Tangentially Clamped Inserts

with a Very Positive Chipformer L

and Reinforced Cutting Edge APMX

RE

Dimensions Tough 1 Hard Recommended MILLING INSERTS

Machining Data

IC328 IC928 IC950 IC808 IC908 IC910 DT7150 IC4100 ap fz

Designation W1 L S RE APMX (1) (mm) (mm/t)

LNKX 1106PN-N MM 6.00 11.16 11.00 0.80 5.00 • • • • • • 1.50-5.00 0.15-0.20

LNKX 1106PNTN MM 6.00 11.16 11.00 0.80 5.00 • • • 1.50-5.00 0.17-0.25

LNMT 1106PN-N MM 6.00 11.16 11.00 0.80 5.00 • • • • • • • 1.50-5.00 0.17-0.25

• Molded chipformer to produce positive cutting • Reduced cutting forces enable higher feed capability • LNKX... is peripherally ground for accuracy and improved surface

finish • LNMT... is an economical utility insert • LNKX1106PNTN MM insert has a reinforced chamfered land • 4 R.H. and 4 L.H. cutting edges when used on F90LN...

cutters • For cutting speed recommendations, see pages 542-547

(1) DOC when the insert is on the cutter

For tools, see pages: F90LN-N11 (203) • FDN-CALN11 (349) • SDN-CALN11 (359)

PN-N-MM PNTN MM

LNHT 1106 PN-R HT S W1

Tangentially Clamped Inserts

with 4 Straight Right-Hand L APMX 10° Ref.

Cutting Edges

RE RE

Dimensions Tough 1 Hard Recommended Machining Data

ap

fz

Designation W1 L S RE APMX (1) IC928 IC908 IC910 (mm) (mm/t)

LNHT 1106PN-R HT 5.97 11.16 11.00 0.80 10.00 • • • 2.00-7.00 0.15-0.25

• Right-hand insert with 4 cutting edges • Can machine a 90° shoulder according to the table below • For cutting speed recommendations, see pages 542-547

(1) APMX=10 mm for cast iron applications (for each pass), APMX=8 mm for steel applications

For tools, see pages: F90LN-N11 (203) • FDN-CALN11 (349) • SDN-CALN11 (359)

Mismatch as a function ∆W

of tool diameter LNHT 11..

∆h=8

Dtool ∆W

40 0.12

50 0.06

63 0.03 8

80 0.04

100 0.01

125 0.02

481