Page 474 - ISCAR(MILLINGCATALOG 38_2021)

P. 474

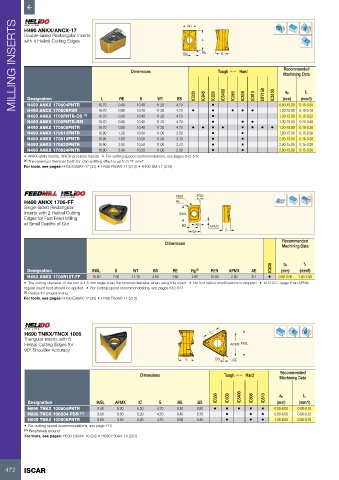

MILLING INSERTS H490 ANKX/ANCX-17 Dimensions BS W1 3 L Tough 1 Hard Recommended

Double-Sided Rectangular Inserts

1

with 4 Helical Cutting Edges

RE

S

Machining Data

ap

fz

RE

Designation

S

(mm/t)

BS

(mm)

W1

L

H490 ANKX 170604PNTR

•

11.20

1.20-15.00

H490 ANCX 170608PDR

0.80

16.70

10.40

4.70

0.10-0.18

•

16.70

10.40

4.70

0.15-0.22

1.20-15.00

0.80

11.20

H490 ANKX 1706PNTR-CS (1) 16.70 0.40 10.40 11.20 4.70 • IC330 IC845 • IC830 IC5400 • IC380 • IC808 • IC810 DT7150 IC5100 0.80-15.00 0.15-0.30

H490 ANKX 1706PNTR-RM 16.70 0.80 10.40 11.20 4.70 • • • 1.20-15.00 0.20-0.40

H490 ANKX 170608PNTR 16.70 0.80 10.40 11.20 4.70 • • • • • • • • 1.20-15.00 0.15-0.30

H490 ANKX 170612PNTR 16.90 1.20 10.50 11.00 3.50 • • 1.60-15.00 0.15-0.30

H490 ANKX 170616PNTR 16.90 1.60 10.50 11.00 3.10 • • 2.00-15.00 0.15-0.30

H490 ANKX 170620PNTR 16.90 2.00 10.50 11.00 2.70 • • 2.40-15.00 0.15-0.30

H490 ANKX 170624PNTR 16.90 2.40 10.50 11.00 2.30 • • 2.80-15.00 0.15-0.30

• ANKX-utility inserts. ANCX-precision inserts • For cutting speed recommendations, see pages 542-547

(1) The maximum feed per tooth for chip splitting effect is up to 0.22 mm/t.

For tools, see pages: H490 E90AX-17 (33) • H490 F90AX-17 (213) • H490 SM-17 (249)

REN 3º30’ Rd°

H490 ANKX 1706-FF RE

Single-Sided Rectangular

Inserts with 2 Helical Cutting lNSL

Edges for Fast Feed Milling

at Small Depths of Cut BS AE APMX

S

W1

Recommended

Dimensions Machining Data

IC830 ap fz

Designation INSL S W1 BS RE Rg (1) REN APMX AE (mm) (mm/t)

H490 ANKX 1706R15T-FF 16.80 7.80 11.70 4.60 1.60 2.85 15.00 2.00 6.1 • 0.50-2.00 1.00-2.00

• The cutting diameter of the tool is 1.5 mm larger than the nominal diameter when using this insert • No tool radius modifications is required • At D.O.C. larger than APMX,

regular insert feed should be applied • For cutting speed recommendations, see pages 542-547

(1) Radius for programming

For tools, see pages: H490 E90AX-17 (33) • H490 F90AX-17 (213)

H690 TNKX/TNCX 1005 IC 2

Triangular Inserts with 6

Helical Cutting Edges for 1 APMX INSL

90° Shoulder Accuracy 3

S BS RE

Recommended

Dimensions Tough 1 Hard Machining Data

IC330 IC830 IC5400 IC808 IC810 ap fz

Designation INSL APMX IC S RE BS (mm) (mm/t)

H690 TNKX 100504PNTR 8.48 8.00 6.20 4.70 0.40 0.80 • • • • • 0.80-8.00 0.08-0.15

H690 TNCX 100504 PDR (1) 8.60 8.00 6.20 4.70 0.40 0.70 • • • 0.80-8.00 0.08-0.13

H690 TNKX 100508PNTR 8.60 8.00 6.20 4.70 0.80 0.40 • • • 1.20-8.00 0.08-0.15

• For cutting speed recommendations, see page 473

(1) Peripherally ground

For tools, see pages: H690 E90AX-10 (28) • H690 F90AX-10 (201)

472 ISCAR