Page 469 - ISCAR(MILLINGCATALOG 38_2021)

P. 469

W1 Rd°

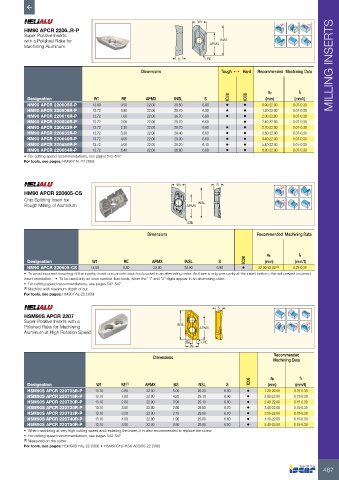

HM90 APCR 2206..R-P

Super Positive Inserts

with a Polished Rake for lNSL

Machining Aluminum APMX

S RE

Dimensions Tough 1 Hard Recommended Machining Data MILLING INSERTS

ap fz

Designation W1 RE APMX INSL S IC28 IC08 (mm) (mm/t)

HM90 APCR 220605R-P 13.90 0.50 22.00 30.50 6.90 • • 0.90-22.00 0.07-0.30

HM90 APCR 220608R-P 13.72 0.80 22.00 29.70 6.90 • • 1.20-22.00 0.07-0.30

HM90 APCR 220616R-P 13.72 1.60 22.00 29.70 6.90 • • 2.00-22.00 0.07-0.30

HM90 APCR 220620R-P 13.72 2.00 22.00 29.70 6.60 • 2.40-22.00 0.07-0.30

HM90 APCR 220623R-P 13.72 2.30 22.00 29.70 6.60 • • 2.70-22.00 0.07-0.30

HM90 APCR 220632R-P 13.72 3.20 22.00 29.40 6.60 • • 3.60-22.00 0.07-0.30

HM90 APCR 220640R-P 13.72 4.00 22.00 29.00 6.60 • • 4.40-22.00 0.07-0.30

HM90 APCR 220650R-P 13.72 5.00 22.00 28.20 6.10 • • 5.40-22.00 0.07-0.30

HM90 APCR 220664R-P 13.72 6.40 22.00 26.80 6.00 • • 6.80-22.00 0.07-0.30

• For cutting speed recommendations, see pages 542-547

For tools, see pages: HM90 FAL-22 (389)

W1 S

HM90 APCR 220605-CS

Chip Splitting Insert for Rd°

Rough Milling of Aluminum APMX lNSL

RE

Dimensions Recommended Machining Data

ap fz

Designation W1 RE APMX INSL S IC28 (mm) (mm/t)

HM90 APCR 220605-CS 14.60 0.50 22.00 30.90 6.90 • 22.00-22.00 (1) 0.25-0.35

• To avoid incorrect mounting of the inserts, insert one pin into each tool pocket in an alternating order. As there is only one cavity at the insert bottom, this will prevent incorrect

insert orientation. • To be used only on even number flute tools, when the "1" and "2" digits appear in an alternating order.

• For cutting speed recommendations, see pages 542-547

(1) Machine with maximum depth of cut

For tools, see pages: HM90 FAL-22 (389)

S

HSM90S APCR 2207

Super Positive Inserts with a Rd°

Polished Rake for Machining INSL APMX

Aluminum at High Rotation Speed

BS RE

W1

Recommended

Dimensions

Machining Data

fz

ap

Designation W1 RE (1) APMX BS INSL S IC08 (mm) (mm/t)

HSM90S APCR 220708R-P 13.10 0.80 22.00 5.00 29.20 6.90 • 1.20-22.00 0.15-0.30

HSM90S APCR 220716R-P 13.10 1.60 22.00 4.20 29.10 6.90 • 2.00-22.00 0.15-0.30

HSM90S APCR 220720R-P 13.10 2.00 22.00 3.90 29.10 6.80 • 2.40-22.00 0.15-0.30

HSM90S APCR 220730R-P 13.10 3.00 22.00 2.90 29.00 6.70 • 3.40-22.00 0.15-0.30

HSM90S APCR 220732R-P 13.10 3.20 22.00 2.70 29.00 6.70 • 3.50-22.00 0.15-0.30

HSM90S APCR 220740R-P 13.10 4.00 22.00 1.90 29.00 6.60 • 4.40-22.00 0.15-0.30

HSM90S APCR 220750R-P 13.10 5.00 22.00 0.90 28.90 6.50 • 5.40-22.00 0.15-0.30

• When machining at very high cutting speed and replacing the insert, it is also recommended to replace the screw

• For cutting speed recommendations, see pages 542-547

(1) Measured on the cutter

For tools, see pages: HSM90S FAL-22 (389) • HSM90SFD-HSK A63/80-22 (390)

467