Page 470 - ISCAR(MILLINGCATALOG 38_2021)

P. 470

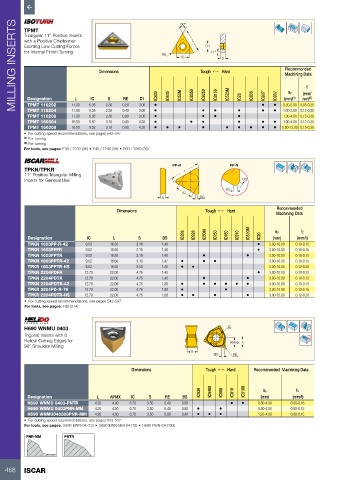

MILLING INSERTS TPMT Dimensions RE 60° L Tough 1 Hard Recommended

Triangular 11° Positive Inserts

with a Positive Chipformer

Exerting Low Cutting Forces

D1

for Internal Finish Turning

11°

IC

S

Machining Data

f

ap

(mm/

Designation

IC

L

S

D1

RE

(2)

(mm)

rev)

(1)

TPMT 110202

•

•

•

0.40

3.00

11.00

6.35

1.00-3.00 0.12-0.30

2.38

TPMT 110204

•

•

•

•

6.35

TPMT 110208 11.00 6.35 2.38 0.20 3.00 • IC830 IC635 IC50M IC8350 • IC8250 • IC8150 IC520M • IC20 IC806 • IC807 • IC907 0.20-2.00 0.05-0.25

2.38

1.00-4.00 0.15-0.30

3.00

0.80

11.00

TPMT 160304 16.50 9.52 3.18 0.40 4.30 • • • • • • 1.00-4.00 0.12-0.30

TPMT 160308 16.50 9.52 3.18 0.80 4.30 • • • • • • • • • 5.00-12.00 0.15-0.35

• For cutting speed recommendations, see pages 542-547

(1) For turning

(2) For turning

For tools, see pages: E30 / T230 (36) • E45 / T245 (38) • E60 / T260 (39)

TPKN/TPKR PP-R L PP-N

11° Positive Triangular Milling

Inserts for General Use BS

BS

IC

S BS

Recommended

Dimensions Tough 1 Hard

Machining Data

IC328 IC928 IC50M IC250 IC950 IC910 IC520M ap fz

Designation IC L S BS IC20 (mm) (mm/t)

TPKN 1603PP-R-42 9.52 16.50 3.18 1.40 • 3.00-10.00 0.10-0.15

TPKN 1603PPFR 9.52 16.50 3.18 1.40 • 3.00-10.00 0.10-0.15

TPKN 1603PPTR 9.52 16.50 3.18 1.40 • • 3.00-10.00 0.10-0.15

TPKN 1603PPTR-42 9.52 16.50 3.18 1.47 • • • 3.00-10.00 0.10-0.15

TPKR 1603PPTR-HS 9.52 16.50 3.50 1.45 • • 3.00-10.00 0.12-0.20

TPKN 2204PDFR 12.70 22.00 4.76 1.40 • 3.00-15.00 0.10-0.15

TPKN 2204PDTR 12.70 22.00 4.76 1.45 • • 3.00-15.00 0.10-0.15

TPKN 2204PDTR-42 12.70 22.00 4.76 1.80 • • • • • • 3.00-15.00 0.10-0.15

TPKR 2204PD-R-76 12.70 22.00 4.76 1.80 • • 3.00-15.00 0.10-0.15

TPKR 2204PDTR-HS 12.70 22.00 4.76 1.88 • • • • 3.00-15.00 0.12-0.20

• For cutting speed recommendations, see pages 542-547

For tools, see pages: F90 (214)

H690 WNMU 0403 IC

Trigonal Inserts with 6 Rd°

Helical Cutting Edges for APMX L

90° Shoulder Milling

S

BS RE

Dimensions Tough 1 Hard Recommended Machining Data

IC830 IC5400 IC808 IC810 IC5100 ap fz

Designation L APMX IC S RE BS (mm) (mm/t)

H690 WNMU 0403-PNTR 4.20 4.00 6.70 3.50 0.40 0.80 • • 0.80-4.00 0.08-0.18

H690 WNMU 0403PNR-MM 4.20 4.00 6.70 3.50 0.40 0.80 • • 0.80-4.00 0.08-0.15

H690 WNMU040308PNR-MM 4.20 4.00 6.70 3.50 0.80 0.40 • • • 1.20-4.00 0.08-0.15

• For cutting speed recommendations, see pages 542-547

For tools, see pages: H690 EWN-04 (12) • H690 EWN-MM-04 (12) • H690 FWN-04 (193)

PNR-MM PNTR

468 ISCAR