Page 467 - ISCAR(MILLINGCATALOG 38_2021)

P. 467

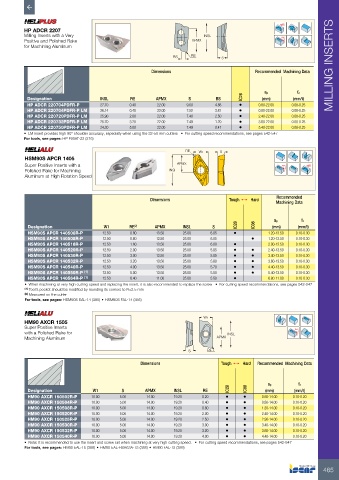

HP ADCR 2207

Milling Inserts with a Very INSL Rd°

Positive and Polished Rake APMX

for Machining Aluminum

BS RE S

Dimensions Recommended Machining Data MILLING INSERTS

ap fz

Designation INSL RE APMX S BS IC28 (mm) (mm/t)

HP ADCR 220704PDFR-P 27.70 0.40 22.00 9.60 4.88 • 0.80-22.00 0.08-0.25

HP ADCR 220704PDFR-P LM 26.14 0.40 22.00 7.52 3.81 • 0.80-22.00 0.08-0.25

HP ADCR 220720PDFR-P LM 25.90 2.00 22.00 7.40 2.50 • 2.40-22.00 0.08-0.25

HP ADCR 220732PDFR-P LM 25.70 3.20 22.00 7.49 1.20 • 3.60-22.00 0.08-0.25

HP ADCR 220750PDFR-P LM 24.30 5.00 22.00 7.49 0.47 • 5.40-22.00 0.08-0.25

• LM insert provides high 90° shoulder accuracy, especially when using the 32-50 mm cutters • For cutting speed recommendations, see pages 542-547

For tools, see pages: HP F90AT-22 (216)

RE W1 S

HSM90S APCR 1405

Super Positive Inserts with a APMX Rd°

Polished Rake for Machining lNSL

Aluminum at High Rotation Speed

Recommended

Dimensions Tough 1 Hard

Machining Data

ap fz

Designation W1 RE (2) APMX INSL S IC28 IC08 (mm) (mm/t)

HSM90S APCR 140508R-P 12.50 0.80 13.50 25.00 6.05 • 1.20-13.50 0.10-0.30

HSM90S APCR 140508R-P 12.50 0.80 13.50 25.00 6.05 • 1.20-13.50 0.10-0.30

HSM90S APCR 140516R-P 12.50 1.60 13.50 25.00 6.00 • 2.00-13.50 0.10-0.30

HSM90S APCR 140520R-P 12.50 2.00 13.50 25.00 5.95 • • 2.40-13.50 0.10-0.30

HSM90S APCR 140530R-P 12.50 3.00 13.50 25.00 5.85 • • 3.40-13.50 0.10-0.30

HSM90S APCR 140532R-P 12.50 3.20 13.50 25.00 5.80 • • 3.60-13.50 0.10-0.30

HSM90S APCR 140540R-P 12.50 4.00 13.50 25.00 5.70 • • 4.40-13.50 0.10-0.30

HSM90S APCR 140550R-P (1) 12.50 5.00 13.50 25.00 5.50 • • 5.40-13.50 0.10-0.30

HSM90S APCR 140564R-P (1) 12.50 6.40 11.00 25.00 5.50 • 6.80-11.00 0.10-0.30

• When machining at very high cutting speed and replacing the insert, it is also recommended to replace the screw • For cutting speed recommendations, see pages 542-547

(1) Tool's pocket should be modified by rounding its corners to R=2.5 mm

(2) Measured on the cutter

For tools, see pages: HSM90S EAL-14 (385) • HSM90S FAL-14 (385)

HM90 AXCR 1505 W1

Super Positive Inserts Rd°

with a Polished Rake for lNSL

Machining Aluminum APMX

S RE

Dimensions Tough 1 Hard Recommended Machining Data

ap fz

Designation W1 S APMX INSL RE IC28 IC08 (mm) (mm/t)

HM90 AXCR 150502R-P 10.00 5.00 14.00 19.20 0.20 • • 0.60-14.00 0.10-0.20

HM90 AXCR 150504R-P 10.00 5.00 14.00 19.20 0.40 • • 0.80-14.00 0.10-0.20

HM90 AXCR 150508R-P 10.00 5.00 14.00 19.20 0.80 • • 1.20-14.00 0.10-0.20

HM90 AXCR 150520R-P 10.00 5.00 14.00 19.20 2.00 • • 2.40-14.00 0.10-0.20

HM90 AXCR 150525R-P 10.00 5.00 14.00 19.20 2.50 • • 2.90-14.00 0.10-0.20

HM90 AXCR 150530R-P 10.00 5.00 14.00 19.20 3.00 • • 3.40-14.00 0.10-0.20

HM90 AXCR 150532R-P 10.00 5.00 14.00 19.20 3.20 • • 3.60-14.00 0.10-0.20

HM90 AXCR 150540R-P 10.00 5.00 14.00 19.20 4.00 • • 4.40-14.00 0.10-0.20

• Note: It is recommended to use the insert and screw set when machining at very high cutting speed. • For cutting speed recommendations, see pages 542-547

For tools, see pages: HM90 EAL-15 (388) • HM90 EAL-HSK63A-15 (388) • HM90 FAL-15 (389)

465