Page 463 - ISCAR(MILLINGCATALOG 38_2021)

P. 463

W1

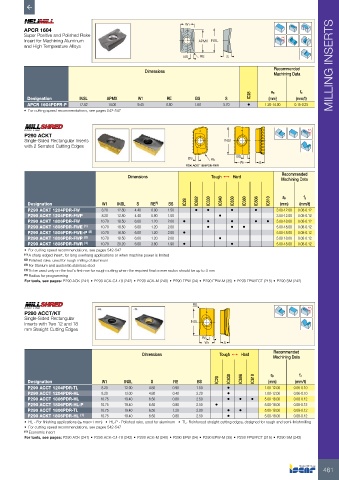

APCR 1604

Super Positive and Polished Rake Rd°

Insert for Machining Aluminum APMX INSL

and High Temperature Alloys

BS RE S

Recommended MILLING INSERTS

Dimensions

Machining Data

IC28 ap fz

Designation INSL APMX W1 RE BS S (mm) (mm/t)

APCR 1604PDFR-P 17.92 14.00 9.45 0.80 1.80 5.70 • 1.20-14.00 0.15-0.25

• For cutting speed recommendations, see pages 542-547

Rd°

P290 ACKT

Single-Sided Rectangular Inserts lNSL

with 2 Serrated Cutting Edges

BS RE BS

W1 S

P290 ACKT 1806PDR-FWR

Recommended

Dimensions Tough 1 Hard Machining Data

ap

fz

Designation W1 INSL S RE (5) BS IC28 IC882 IC330 IC840 IC830 IC380 IC808 IC810 (mm) (mm/t)

P290 ACKT 1204PDR-FW 8.20 12.80 4.40 0.90 1.50 • • • • 3.00-12.00 0.08-0.12

P290 ACKT 1204PDR-FWP 8.20 12.80 4.40 0.90 1.50 • 3.00-12.00 0.08-0.12

P290 ACKT 1806PDR-FW 10.70 18.50 6.00 1.20 2.00 • • • • • 5.00-18.00 0.08-0.12

P290 ACKT 1806PDR-FWE (1) 10.70 18.50 6.00 1.20 2.00 • • • 5.00-18.00 0.08-0.12

P290 ACKT 1806PDR-FWE-P (2) 10.70 18.50 6.00 1.20 2.00 • 5.00-18.00 0.08-0.12

P290 ACKT 1806PDR-FWP (3) 10.70 18.50 6.00 1.20 2.00 • 5.00-18.00 0.08-0.12

P290 ACKT 1806PDR-FWR (4) 10.70 20.20 6.00 3.80 1.90 • • 5.00-18.00 0.08-0.12

• For cutting speed recommendations, see pages 542-547

(1) A sharp edged insert, for long overhang applications or when machine power is limited

(2) Polished rake, used for rough milling of aluminum

(3) For titanium and austenitic stainless steel

(4) To be used only on the tool's first row for rough cutting when the required final corner radius should be up to 4 mm

(5) Radius for programming

For tools, see pages: P290 ACK (241) • P290 ACK-C#-18 (242) • P290 ACK-M (240) • P290 EPW (34) • P290 EPW-M (35) • P290 FPW/FCT (215) • P290 SM (242)

RE Rd°

P290 ACCT/KT

Single-Sided Rectangular

Inserts with Two 12 and 18 lNSL

mm Straight Cutting Edges

BS

W1 S

Recommended

Dimensions Tough 1 Hard

Machining Data

ap

fz

Designation W1 INSL S RE BS IC28 IC830 IC808 IC810 (mm) (mm/t)

P290 ACCT 1204PDR-TL 8.20 12.90 4.80 0.90 1.50 • 1.00-12.00 0.06-0.10

P290 ACCT 1204PDR-HL 8.20 13.00 4.80 0.40 2.20 • 1.00-12.00 0.06-0.10

P290 ACCT 1806PDR-HL 10.75 19.40 6.50 0.80 2.50 • • • 5.00-18.00 0.08-0.12

P290 ACCT 1806PDR-HL-P 10.75 19.40 6.50 0.80 2.50 • 5.00-18.00 0.08-0.12

P290 ACCT 1806PDR-TL 10.75 19.40 6.50 1.20 2.00 • • 5.00-18.00 0.08-0.12

P290 ACKT 1806PDR-HL (1) 10.75 19.40 6.50 0.80 2.50 • 5.00-18.00 0.08-0.12

• HL - For finishing applications (ae max=1 mm) • HL-P - Polished rake, used for aluminum • TL- Reinforced straight cutting edges, designed for rough and semi-finishmilling

• For cutting speed recommendations, see pages 542-547

(1) Economic insert

For tools, see pages: P290 ACK (241) • P290 ACK-C#-18 (242) • P290 ACK-M (240) • P290 EPW (34) • P290 EPW-M (35) • P290 FPW/FCT (215) • P290 SM (242)

461