Page 73 - ISCAR(MILLINGCATALOG 38_2021)

P. 73

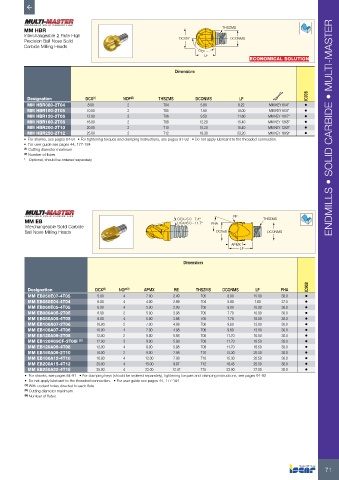

MM HBR THSZMS

Interchangeable 2 Flute High DCXh7 DCONMS

Precision Ball Nose Solid

Carbide Milling Heads

120°

LF

ECONOMICAL SOLUTION

Dimensions

IC908

Designation DCX (1) NOF (2) THSZMS DCONMS LF

MM HBR080-2T04 8.00 2 T04 5.80 8.22 MM KEY 6X4* •

MM HBR100-2T05 10.00 2 T05 7.60 10.00 MM KEY 6X4* •

MM HBR120-2T06 12.00 2 T06 9.50 11.60 MM KEY 10X7* •

MM HBR160-2T08 16.00 2 T08 12.20 15.40 MM KEY 13X8* •

MM HBR200-2T10 20.00 2 T10 15.20 18.40 MM KEY 13X8* • ENDMILLS • SOLID CARBIDE • MULTI-MASTER

MM HBR250-2T12 25.00 2 T12 18.30 23.20 MM KEY 16X9* •

• For shanks, see pages 84-91 • For tightening torques and clamping instructions, see pages 91-92 • Do not apply lubricant to the threaded connection.

• For user guide see pages 44, 177-184

(1) Cutting diameter maximum

(2) Number of flutes

* Optional, should be ordered separately

RE

MM EB DCX=5.0 - 7.4° FHA THSZMS

DCX=6.0 - 11.7°

Interchangeable Solid Carbide

Ball Nose Milling Heads DCXe8 DCONMS

APMX

LF

Dimensions

IC908

Designation DCX (2) NOF (3) APMX RE THSZMS DCONMS LF FHA

MM EB050E07-4T05 5.00 4 7.00 2.49 T05 8.00 15.00 38.0 •

MM EB060E04-4T04 6.00 4 4.00 2.99 T04 5.80 7.60 37.0 •

MM EB060E05-4T05 6.00 4 5.00 2.99 T05 8.00 10.00 38.0 •

MM EB080A05-2T05 8.00 2 5.00 3.98 T05 7.70 10.00 30.0 •

MM EB080A05-4T05 8.00 4 5.00 3.98 T05 7.70 10.00 30.0 •

MM EB100A07-2T06 10.00 2 7.00 4.98 T06 9.60 13.00 30.0 •

MM EB100A07-4T06 10.00 4 7.00 4.98 T06 9.60 13.00 30.0 •

MM EB120A09-2T08 12.00 2 9.00 5.98 T08 11.70 16.50 30.0 •

MM EB120H09CF-3T08I (1) 12.00 3 9.00 5.98 T08 11.70 16.50 38.0 •

MM EB120A09-4T08 12.00 4 9.00 5.98 T08 11.70 16.50 30.0 •

MM EB160A09-2T10 16.00 2 9.00 7.98 T10 15.30 20.50 30.0 •

MM EB160A12-4T10 16.00 4 12.00 7.98 T10 15.30 20.50 30.0 •

MM EB200A15-4T12 20.00 4 15.00 9.97 T12 18.45 25.50 30.0 •

MM EB250A22-4T15 25.00 4 22.00 12.47 T15 23.90 37.00 30.0 •

• For shanks, see pages 84-91 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 91-92

• Do not apply lubricant to the threaded connection. • For user guide see pages 44, 177-184

(1) With coolant holes directed to each flute

(2) Cutting diameter maximum

(3) Number of flutes

71