Page 381 - ISCAR(TURNING-CATALOG-42-2022)

P. 381

CDX Ø17

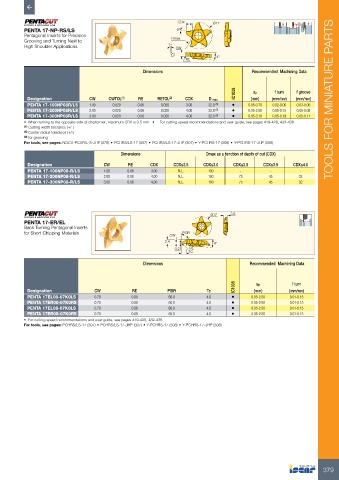

PENTA 17-NP-RS/LS 9°

Pentagonal Inserts for Precision Dmax

Grooving and Turning Next to

High Shoulder Applications 7° CW

4°

RE

Dimensions Recommended Machining Data

IC1008 ap f turn f groove

Designation CW CWTOL (1) RE RETOL (2) CDX D max (mm) (mm/rev) (mm/rev) TOOLS FOR MINIATURE PARTS

PENTA 17-100NP08R/LS 1.00 0.020 0.08 0.020 3.00 32.0 (3) • 0.05-0.70 0.02-0.06 0.03-0.06

PENTA 17-200NP08R/LS 2.00 0.020 0.08 0.020 4.00 32.0 • 0.05-2.50 0.05-0.15 0.05-0.09

(3)

PENTA 17-300NP08R/LS 3.00 0.020 0.08 0.020 4.00 32.0 • 0.05-3.10 0.05-0.19 0.05-0.11

(3)

• When turning to the opposite side of chipformer, maximum CDX is 0.5 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) for grooving

For tools, see pages: NQCH-PCHR/L-S-JHP (378) • PCHRS/LS-17 (307) • PCHRS/LS-17-JHP (307) • Y-PCHRS-17 (308) • Y-PCHRS-17-JHP (308)

Dimensions Dmax as a function of depth of cut (CDX)

Designation CW RE CDX CDX≤2.5 CDX≤3.0 CDX≤3.5 CDX≤3.8 CDX≤4.0

PENTA 17-100NP08-R/LS 1.00 0.08 3.00 N.L. 100 - - -

PENTA 17-200NP08-R/LS 2.00 0.08 4.00 N.L. 100 75 45 32

PENTA 17-300NP08-R/LS 3.00 0.08 4.00 N.L. 100 75 45 32

Ø17 3.5

PENTA 17-ER/EL

Back Turning Pentagonal Inserts

for Short Chipping Materials PSIR

CW

2.4 4°

0.2 RE

TC

Dimensions Recommended Machining Data

IC1008 ap f turn

Designation CW RE PSIR Tc (mm) (mm/rev)

PENTA 17EL00-07K0LS 0.70 0.00 60.0 4.0 • 0.05-2.50 0.01-0.15

PENTA 17ER00-07K0RS 0.70 0.00 60.0 4.0 • 0.05-2.50 0.01-0.15

PENTA 17EL08-07K0LS 0.70 0.08 60.0 4.0 • 0.05-2.50 0.01-0.15

PENTA 17ER08-07K0RS 0.70 0.08 60.0 4.0 • 0.05-2.50 0.01-0.15

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

For tools, see pages: PCHRS/LS-17 (307) • PCHRS/LS-17-JHP (307) • Y-PCHRS-17 (308) • Y-PCHRS-17-JHP (308)

379