Page 377 - ISCAR(TURNING-CATALOG-42-2022)

P. 377

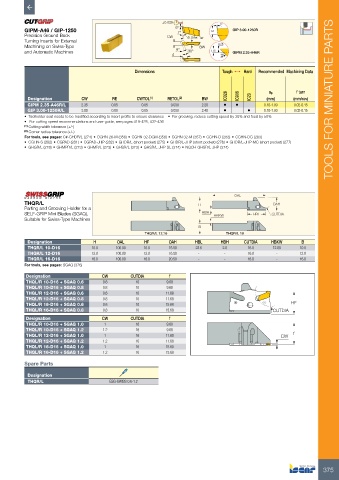

±0.025 2°

GIPM-A46 / GIP-1250 6° 7° 1.2 GIP 3.00-1250R

Precision Ground Back CW

Turning Inserts for External 15.3 Ref.

Machining on Swiss-Type BW 0.25

and Automatic Machines 8° 30° 1.15 GIPM 2.35-A46R

4 46°

Dimensions Tough 1 Hard Recommended Machining Data

IC328 IC908 ap f turn

Designation CW RE CWTOL (1) RETOL (2) BW IC20 (mm) (mm/rev) TOOLS FOR MINIATURE PARTS

GIPM 2.35-A46R/L 2.35 0.05 0.05 0.030 2.20 • • 0.10-1.00 0.02-0.15

GIP 3.00-1250R/L 3.00 0.00 0.05 0.030 2.40 • • 0.10-1.00 0.02-0.15

• Toolholder seat needs to be modified according to insert profile to ensure clearance • For grooving, reduce cutting speed by 30% and feed by 50%

• For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: C#-GHDR/L (274) • CGHN 26-M (356) • CGHN 32-DGM (358) • CGHN 32-M (357) • CGHN-D (283) • CGHN-DG (283)

• CGHN-S (282) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276) • GHDR/L-JHP-MC (short pocket) (277)

• GHGR/L (278) • GHMPR/L (273) • GHMR/L (273) • GHSR/L (373) • GHSR/L-JHP-SL (374) • NQCH-GHSR/L-JHP (374)

OAL

THQR/L H OAH

Parting and Grooving Holder for a

SELF-GRIP Mini Blades (SGAQ), HBH HBKW HBL CUTDIA

Suitable for Swiss-Type Machines

B

THQR/L 12,16 THQR/L 10

Designation H OAL HF OAH HBL HBH CUTDIA HBKW B

THQR/L 10-D16 10.0 100.00 10.0 16.50 22.6 2.0 16.0 12.00 10.0

THQR/L 12-D16 12.0 100.00 12.0 16.50 - - 16.0 - 12.0

THQR/L 16-D16 16.0 100.00 16.0 20.50 - - 16.0 - 16.0

For tools, see pages: SGAQ (376)

Designation CW CUTDIA f

THQL/R 10-D16 + SGAQ 0.6 0.6 10 9.68

THQL/R 10-D16 + SGAQ 0.8 0.8 10 9.68

THQL/R 12-D16 + SGAQ 0.6 0.6 10 11.68

THQL/R 12-D16 + SGAQ 0.8 0.8 10 11.68

THQL/R 16-D16 + SGAQ 0.6 0.6 10 15.68 HF

THQL/R 16-D16 + SGAQ 0.8 0.8 10 15.68 CUTDIA

Designation CW CUTDIA f

THQL/R 10-D16 + SGAQ 1.0 1 16 9.60

THQL/R 10-D16 + SGAQ 1.2 1.2 16 9.68

THQL/R 12-D16 + SGAQ 1.0 1 16 11.60 CW f

THQL/R 12-D16 + SGAQ 1.2 1.2 16 11.68

THQL/R 16-D16 + SGAQ 1.0 1 16 15.60

THQL/R 16-D16 + SGAQ 1.2 1.2 16 15.68

Spare Parts

Designation

THQR/L ESG-SWISS 0.6-1.2

375