Page 374 - ISCAR(TURNING-CATALOG-42-2022)

P. 374

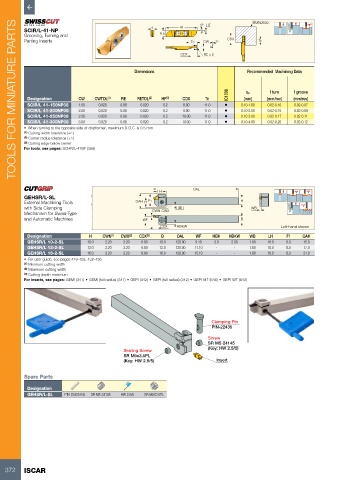

9° HF Workpiece

TOOLS FOR MINIATURE PARTS

SCIR/L-41-NP 4 41

Grooving, Turning and 8.5

Parting Inserts Tc CW 7° CDX Tc

CDX RE x 2

Dimensions Recommended Machining Data

IC1008 ap f turn f groove

Designation CW CWTOL (1) RE RETOL (2) HF (3) CDX Tc (mm) (mm/rev) (mm/rev)

SCIR/L 41-150NP08 1.50 0.020 0.08 0.020 0.2 8.00 11.0 • 0.10-1.80 0.02-0.10 0.02-0.07

SCIR/L 41-200NP08 2.00 0.020 0.08 0.020 0.2 8.00 11.0 • 0.10-2.50 0.02-0.15 0.02-0.09

SCIR/L 41-250NP08 2.50 0.020 0.08 0.020 0.2 10.00 11.0 • 0.10-3.00 0.02-0.17 0.02-0.11

SCIR/L 41-300NP08 3.00 0.020 0.08 0.020 0.2 10.00 11.0 • 0.10-4.00 0.02-0.20 0.02-0.12

• When turning to the opposite side of chipformer, maximum D.O.C. is 0.5 mm

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting edge below center

For tools, see pages: SCHR/L-41BF (369)

LH OAL

GEHSR/L-SL

External Machining Tools OAH H F1 H

with Side Clamping HBH WB

Mechanism for Swiss-Type CWN-CWX

and Automatic Machines WF B

CDX HBKW Left-hand shown

Designation H CWN (1) CWX (2) CDX (3) B OAL WF HBH HBKW WB LH F1 OAH

GEHSR/L 10-2-SL 10.0 2.20 3.20 6.80 10.0 120.00 9.10 2.0 2.00 1.80 18.0 8.0 15.0

GEHSR/L 12-2-SL 12.0 2.20 3.20 6.80 12.0 120.00 11.10 - - 1.80 18.0 8.0 17.0

GEHSR/L 16-2-SL 16.0 2.20 3.20 6.80 16.0 120.00 15.10 - - 1.80 18.0 8.0 21.0

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Cutting depth maximum

For inserts, see pages: GEMI (341) • GEMI (full radius) (341) • GEPI (342) • GEPI (full radius) (342) • GEPI-MT (648) • GEPI-WT (642)

Clamping Pin

PIN-22435

Screw

SR M5-24145

(Key: HW 2.5/5)

Sealing Screw

SR M5x3.5PL

(Key: HW 2.5/5) Insert

Spare Parts

Designation

GEHSR/L-SL PIN-22435 INJ SR M5-24145 HW 2.5/5 SR M5X3.5PL

372 ISCAR