Page 371 - ISCAR(TURNING-CATALOG-42-2022)

P. 371

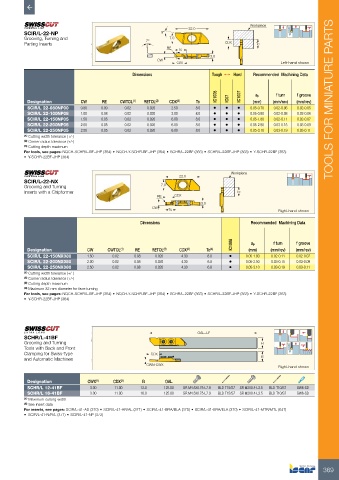

22.0 Workpiece

SCIR/L-22-NP 9°

Grooving, Turning and 7° 7.0

Parting Inserts CDX Tc

RE Tc

3.0

CW

CDX Left-hand shown

Dimensions Tough 1 Hard Recommended Machining Data

IC1008 IC1007 ap f turn f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) Tc IC07 (mm) (mm/rev) (mm/rev) TOOLS FOR MINIATURE PARTS

SCIR/L 22-080NP00 0.80 0.00 0.02 0.020 2.50 8.0 • • • 0.05-0.70 0.02-0.06 0.02-0.05

SCIR/L 22-100NP08 1.00 0.08 0.02 0.020 3.00 8.0 • • • 0.05-0.80 0.02-0.08 0.02-0.06

SCIR/L 22-150NP05 1.50 0.05 0.02 0.020 6.00 8.0 • • • 0.05-1.80 0.02-0.11 0.02-0.07

SCIR/L 22-200NP05 2.00 0.05 0.02 0.020 6.00 8.0 • • • 0.05-2.50 0.03-0.15 0.03-0.09

SCIR/L 22-250NP05 2.50 0.05 0.02 0.020 6.00 8.0 • • • 0.05-3.10 0.03-0.19 0.03-0.11

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: NQCH-SCHR/L-BF-JHP (364) • NQCH-Y-SCHR-BF-JHP (364) • SCHR/L-22BF (363) • SCHR/L-22BF-JHP (363) • Y-SCHR-22BF (363)

• Y-SCHR-22BF-JHP (364)

22.0 Workpiece

SCIR/L-22-NX

Grooving and Turning 7.0

Inserts with a Chipformer Tc

RE CDX

3.0

CW

Tc Right-hand shown

Dimensions Recommended Machining Data

IC1008 ap f turn f groove

Designation CW CWTOL (1) RE RETOL (2) CDX (3) Tc (4) (mm) (mm/rev) (mm/rev)

SCIR/L 22-150NX080 1.50 0.02 0.08 0.020 4.30 6.8 • 0.05-1.80 0.02-0.11 0.02-0.07

SCIR/L 22-200NX080 2.00 0.02 0.08 0.020 4.30 6.8 • 0.05-2.50 0.03-0.15 0.03-0.09

SCIR/L 22-250NX080 2.50 0.02 0.08 0.020 4.30 6.8 • 0.05-3.10 0.03-0.19 0.03-0.11

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

(4) Maximum 32 mm diameter for face turning

For tools, see pages: NQCH-SCHR/L-BF-JHP (364) • NQCH-Y-SCHR-BF-JHP (364) • SCHR/L-22BF (363) • SCHR/L-22BF-JHP (363) • Y-SCHR-22BF (363)

• Y-SCHR-22BF-JHP (364)

SCHR/L-41BF OAL=LF

Grooving and Turning H

Tools with Back and Front

Clamping for Swiss-Type CDX B

and Automatic Machines

CWN-CWX Right-hand shown

Designation CWX (1) CDX (2) B OAL

SCHR/L 12-41BF 3.00 11.00 12.0 125.00 SR M4.5X0.75-L7.9 BLD T15/S7 SR M2X0.4-L3.5 BLD T10/S7 SW6-SD

SCHR/L 16-41BF 3.00 11.00 16.0 125.00 SR M4.5X0.75-L7.9 BLD T15/S7 SR M2X0.4-L3.5 BLD T10/S7 SW6-SD

(1) Maximum cutting width

(2) See insert data

For inserts, see pages: SCIR/L-41-AD (370) • SCIR/L-41-AR/AL (371) • SCIR/L-41-BRA/BLA (370) • SCIR/L-41-ERA/ELA (370) • SCIR/L-41-MTR/MTL (647)

• SCIR/L-41-N/R/L (371) • SCIR/L-41-NP (372)

369