Page 368 - ISCAR(TURNING-CATALOG-42-2022)

P. 368

GAN

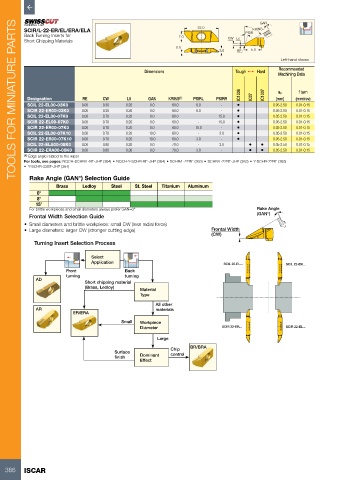

TOOLS FOR MINIATURE PARTS

SCIR/L-22-ER/EL/ERA/ELA 22.0 KRINS

Back Turning Inserts for 7.0 PSIR

Short Chipping Materials CW L5

0.5

3.0 RE 5.0

Left-hand shown

Dimensions Tough 1 Hard Recommended

Machining Data

IC1008 IC1007 ap f turn

Designation RE CW L5 GAN KRINS (1) PSIRL PSIRR IC07 (mm) (mm/rev)

SCIL 22-EL00-03K0 0.00 0.30 0.20 0.0 60.0 6.0 - • 0.05-2.50 0.01-0.15

SCIR 22-ER00-03K0 0.00 0.30 0.20 0.0 60.0 6.0 - • 0.05-2.50 0.01-0.15

SCIL 22-EL00-07K0 0.00 0.70 0.20 0.0 60.0 - 15.0 • 0.05-2.50 0.01-0.15

SCIR 22-EL00-07K0 0.00 0.70 0.20 0.0 60.0 - 15.0 • 0.05-2.50 0.01-0.15

SCIR 22-ER00-07K0 0.00 0.70 0.20 0.0 60.0 15.0 - • 0.05-2.50 0.01-0.15

SCIL 22-EL00-07K10 0.00 0.70 0.20 10.0 60.0 - 3.0 • 0.05-2.50 0.01-0.15

SCIR 22-ER00-07K10 0.00 0.70 0.20 10.0 60.0 3.0 - • 0.05-2.50 0.01-0.15

SCIL 22-ELA00-08K0 0.00 0.80 0.30 0.0 70.0 - 3.0 • • 0.05-2.50 0.01-0.15

SCIR 22-ERA00-08K0 0.00 0.80 0.30 0.0 70.0 3.0 - • • 0.05-2.50 0.01-0.15

(1) Edge angle related to the wiper

For tools, see pages: NQCH-SCHR/L-BF-JHP (364) • NQCH-Y-SCHR-BF-JHP (364) • SCHR/L-22BF (363) • SCHR/L-22BF-JHP (363) • Y-SCHR-22BF (363)

• Y-SCHR-22BF-JHP (364)

Rake Angle (GAN°) Selection Guide

Brass Ledloy Steel St. Steel Titanium Aluminum

0°

8°

15°

For brittle workpieces and small diameters always prefer GAN=0° Rake Angle

(GAN°)

Frontal Width Selection Guide

• Small diameters and brittle workpiece: small CW (less radial force)

• Large diameters: larger CW (stronger cutting edge) Frontal Width

(CW)

Turning Insert Selection Process

Select

Application SCIL 22-EL... SCIL 22-ER...

Front Back

turning turning

AD

Short chipping material

(Brass, Ledloy)

Material

Type

All other

AR materials

ER/ERA

Small Workpiece

Diameter SCIR 22-ER... SCIR 22-EL...

Large

BR/BRA

Chip

Surface control

finish Dominant

Effect

366 ISCAR