Page 168 - 21-036 APPLITEC catalogue.indb

P. 168

a p

a e

f z

d 1

v c

v f

Q

n

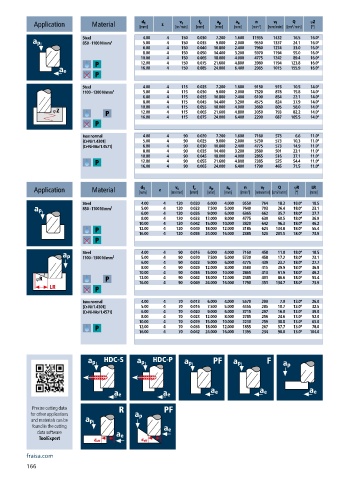

Application Material [mm] z [m/min] [mm] [mm] [mm] [min ] -1 [mm/min] [cm /min] jZ

3

[°]

Steel 4.00 4 150 0.030 7.200 1.600 11935 1432 16.5 16.0°

850 - 1100 N/mm² 5.00 4 150 0.035 9.000 2.000 9550 1337 24.1 16.0°

6.00 4 150 0.040 10.800 2.400 7960 1274 33.0 16.0°

8.00 4 150 0.050 14.400 3.200 5970 1194 55.0 16.0°

10.00 4 150 0.065 18.000 4.000 4775 1242 89.4 16.0°

12.00 4 150 0.075 21.600 4.800 3980 1194 123.8 16.0°

16.00 4 150 0.085 24.000 6.400 2985 1015 155.9 16.0°

Steel 4.00 4 115 0.025 7.200 1.600 9150 915 10.5 14.0°

1100 - 1300 N/mm² 5.00 4 115 0.030 9.000 2.000 7320 878 15.8 14.0°

6.00 4 115 0.035 10.800 2.400 6100 854 22.1 14.0°

8.00 4 115 0.045 14.400 3.200 4575 824 37.9 14.0°

10.00 4 115 0.055 18.000 4.000 3660 805 58.0 14.0°

12.00 4 115 0.065 21.600 4.800 3050 793 82.2 14.0°

16.00 4 115 0.075 24.000 6.400 2290 687 105.5 14.0°

Inox normal 4.00 4 90 0.020 7.200 1.600 7160 573 6.6 11.0°

[Cr-Ni/1.4301] 5.00 4 90 0.025 9.000 2.000 5730 573 10.3 11.0°

[Cr-Ni-Mo/1.4571] 6.00 4 90 0.030 10.800 2.400 4775 573 14.9 11.0°

8.00 4 90 0.035 14.400 3.200 3580 501 23.1 11.0°

10.00 4 90 0.045 18.000 4.000 2865 516 37.1 11.0°

12.00 4 90 0.055 21.600 4.800 2385 525 54.4 11.0°

16.00 4 90 0.065 24.000 6.400 1790 465 71.5 11.0°

a p

a e

n

f z

v f

LR

v c

Q

d 1

Application Material [mm] z [m/min] [mm] [mm] [mm] [min ] [mm/min] [cm /min] jR [mm]

3

[°]

-1

Steel 4.00 4 120 0.020 6.000 4.000 9550 764 18.3 18.0° 18.5

850 - 1100 N/mm² 5.00 4 120 0.023 7.500 5.000 7640 703 26.4 18.0° 23.1

6.00 4 120 0.026 9.000 6.000 6365 662 35.7 18.0° 27.7

8.00 4 120 0.033 12.000 8.000 4775 630 60.5 18.0° 36.9

10.00 4 120 0.042 15.000 10.000 3820 642 96.3 18.0° 46.2

12.00 4 120 0.049 18.000 12.000 3185 624 134.8 18.0° 55.4

16.00 4 120 0.055 24.000 16.000 2385 525 201.5 18.0° 73.9

Steel 4.00 4 90 0.016 6.000 4.000 7160 458 11.0 18.0° 18.5

1100 - 1300 N/mm² 5.00 4 90 0.020 7.500 5.000 5730 458 17.2 18.0° 23.1

6.00 4 90 0.023 9.000 6.000 4775 439 23.7 18.0° 27.7

8.00 4 90 0.029 12.000 8.000 3580 415 39.9 18.0° 36.9

10.00 4 90 0.036 15.000 10.000 2865 413 61.9 18.0° 46.2

12.00 4 90 0.042 18.000 12.000 2385 401 86.6 18.0° 55.4

16.00 4 90 0.049 24.000 16.000 1790 351 134.7 18.0° 73.9

Inox normal 4.00 4 70 0.013 6.000 4.000 5570 290 7.0 13.0° 26.0

[Cr-Ni/1.4301] 5.00 4 70 0.016 7.500 5.000 4455 285 10.7 13.0° 32.5

[Cr-Ni-Mo/1.4571] 6.00 4 70 0.020 9.000 6.000 3715 297 16.0 13.0° 39.0

8.00 4 70 0.023 12.000 8.000 2785 256 24.6 13.0° 52.0

10.00 4 70 0.029 15.000 10.000 2230 259 38.8 13.0° 65.0

12.00 4 70 0.036 18.000 12.000 1855 267 57.7 13.0° 78.0

16.00 4 70 0.042 24.000 16.000 1395 234 90.0 13.0° 104.0

Precise cutting data

for other applications

and materials can be

found in the cutting

data software

ToolExpert

fraisa.com

166