Page 296 - 21-036 APPLITEC catalogue.indb

P. 296

a e

n

v f

a p

d 1

v c

f z

Q

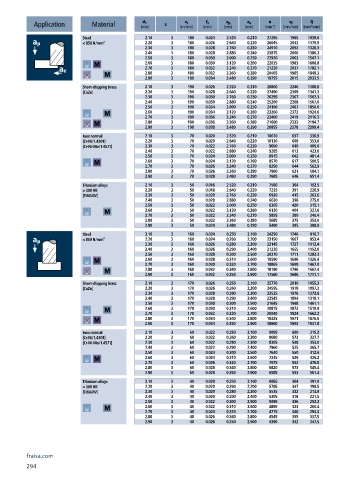

Application Material [mm] z [m/min] [mm] [mm] [mm] [min ] -1 [mm/min] [mm /min]

3

Steel 2.10 3 180 0.024 2.520 0.210 27285 1965 1039.6

< 850 N/mm² 2.20 3 180 0.026 2.640 0.220 26045 2032 1179.9

2.30 3 180 0.028 2.760 0.230 24910 2092 1328.3

2.40 3 180 0.028 2.880 0.240 23875 2006 1386.2

2.50 3 180 0.030 3.000 0.250 22920 2063 1547.1

2.60 3 180 0.030 3.120 0.260 22035 1983 1608.8

2.70 3 180 0.032 3.240 0.270 21220 2037 1782.1

2.80 3 180 0.032 3.360 0.280 20465 1965 1848.3

2.90 3 180 0.034 3.480 0.290 19755 2015 2033.5

Short-chipping brass 2.10 3 190 0.026 2.520 0.210 28800 2246 1188.8

[CuZn] 2.20 3 190 0.028 2.640 0.220 27490 2309 1341.2

2.30 3 190 0.030 2.760 0.230 26295 2367 1502.3

2.40 3 190 0.030 2.880 0.240 25200 2268 1567.6

2.50 3 190 0.034 3.000 0.250 24190 2467 1850.6

2.60 3 190 0.034 3.120 0.260 23260 2373 1924.6

2.70 3 190 0.036 3.240 0.270 22400 2419 2116.3

2.80 3 190 0.036 3.360 0.280 21600 2333 2194.7

2.90 3 190 0.038 3.480 0.290 20855 2378 2399.4

Inox normal 2.10 3 70 0.020 2.520 0.210 10610 637 336.9

[Cr-Ni/1.4301] 2.20 3 70 0.020 2.640 0.220 10130 608 353.0

[Cr-Ni-Mo/1.4571] 2.30 3 70 0.022 2.760 0.230 9690 640 406.0

2.40 3 70 0.022 2.880 0.240 9285 613 423.6

2.50 3 70 0.024 3.000 0.250 8915 642 481.4

2.60 3 70 0.024 3.120 0.260 8570 617 500.5

2.70 3 70 0.026 3.240 0.270 8250 644 562.9

2.80 3 70 0.026 3.360 0.280 7960 621 584.1

2.90 3 70 0.028 3.480 0.290 7685 646 651.4

Titanium alloys 2.10 3 50 0.016 2.520 0.210 7580 364 192.5

> 300 HB 2.20 3 50 0.018 2.640 0.220 7235 391 226.9

[Ti6Al4V] 2.30 3 50 0.020 2.760 0.230 6920 415 263.6

2.40 3 50 0.020 2.880 0.240 6630 398 275.0

2.50 3 50 0.022 3.000 0.250 6365 420 315.1

2.60 3 50 0.022 3.120 0.260 6120 404 327.6

2.70 3 50 0.022 3.240 0.270 5895 389 340.4

2.80 3 50 0.022 3.360 0.280 5685 375 353.0

2.90 3 50 0.024 3.480 0.290 5490 395 398.9

Steel 2.10 3 160 0.024 0.250 2.100 24250 1746 916.7

< 850 N/mm² 2.20 3 160 0.024 0.260 2.200 23150 1667 953.4

2.30 3 160 0.026 0.280 2.300 22145 1727 1112.4

2.40 3 160 0.026 0.290 2.400 21220 1655 1152.0

2.50 3 160 0.028 0.300 2.500 20370 1711 1283.3

2.60 3 160 0.028 0.310 2.600 19590 1646 1326.4

2.70 3 160 0.030 0.320 2.700 18865 1698 1467.0

2.80 3 160 0.032 0.340 2.800 18190 1746 1662.4

2.90 3 160 0.032 0.350 2.900 17560 1686 1711.1

Short-chipping brass 2.10 3 170 0.026 0.250 2.100 25770 2010 1055.3

[CuZn] 2.20 3 170 0.026 0.260 2.200 24595 1918 1097.3

2.30 3 170 0.028 0.280 2.300 23525 1976 1272.6

2.40 3 170 0.028 0.290 2.400 22545 1894 1318.1

2.50 3 170 0.030 0.300 2.500 21645 1948 1461.1

2.60 3 170 0.030 0.310 2.600 20815 1873 1510.0

2.70 3 170 0.032 0.320 2.700 20040 1924 1662.2

2.80 3 170 0.034 0.340 2.800 19325 1971 1876.6

2.90 3 170 0.034 0.350 2.900 18660 1903 1931.8

Inox normal 2.10 3 60 0.022 0.250 2.100 9095 600 315.2

[Cr-Ni/1.4301] 2.20 3 60 0.022 0.260 2.200 8680 573 327.7

[Cr-Ni-Mo/1.4571] 2.30 3 60 0.022 0.280 2.300 8305 548 353.0

2.40 3 60 0.022 0.290 2.400 7960 525 365.7

2.50 3 60 0.024 0.300 2.500 7640 550 412.6

2.60 3 60 0.024 0.310 2.600 7345 529 426.2

2.70 3 60 0.026 0.320 2.700 7075 552 476.8

2.80 3 60 0.028 0.340 2.800 6820 573 545.4

2.90 3 60 0.028 0.350 2.900 6585 553 561.4

Titanium alloys 2.10 3 40 0.020 0.250 2.100 6065 364 191.0

> 300 HB 2.20 3 40 0.020 0.260 2.200 5785 347 198.5

[Ti6Al4V] 2.30 3 40 0.020 0.280 2.300 5535 332 213.9

2.40 3 40 0.020 0.290 2.400 5305 318 221.5

2.50 3 40 0.022 0.300 2.500 5095 336 252.2

2.60 3 40 0.022 0.310 2.600 4895 323 260.4

2.70 3 40 0.024 0.320 2.700 4715 340 293.3

2.80 3 40 0.026 0.340 2.800 4545 355 337.5

2.90 3 40 0.026 0.350 2.900 4390 342 347.5

fraisa.com

294