Page 90 - GARR_TOOL(CATALOG_INT)

P. 90

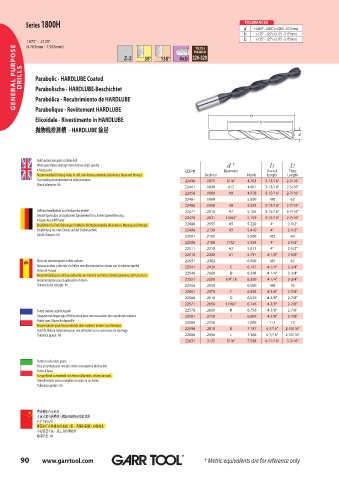

Series 1800H TOLERANCES

d +.0000" –.0005" (+.0000 –.0127mm)

l1 +.125" –.125" (+3.175 –3.175mm)

.1875" - .3125" 8xD 326-329 l2 +.125" –.125" (+3.175 –3.175mm)

(4.763mm - 7.938mm)

GENERAL PURPOSE DRILLS Parabolic - HARDLUBE Coated

Parabolische - HARDLUBE-Beschichtet

Parabólica - Recubrimiento de HARDLUBE

Parabolique - Revêtement HARDLUBE

Elicoidale - Rivestimento in HARDLUBE

抛物线排屑槽 - HARDLUBE 涂层

抛物线排屑槽 涂层

Solid submicron grain carbide drill

Wide open flutes and high helix remove chips quickly d † l1 l2

4-facet point EDP# Diameter Overall Flute

Recommended for deep holes in soft, non-ferrous materials (aluminum, brass and bronze) Decimal Metric Length Length

Live tooling recommended on lathe processes 22436 .1875 3/16" 4.763 3-13/16" 2-5/16"

Shank tolerance: h6

22441 .1890 #12 4.801 3-13/16" 2-5/16"

22456 .1960 #9 4.978 3-15/16" 2-7/16"

22461 .1969 5.000 100 62

22466 .1990 #8 5.055 3-15/16" 2-7/16"

Vollhartmetallbohrer aus Feinkornhartmetall 22471 .2010 #7 5.105 3-15/16" 2-7/16"

Grosse Spannuten und grösserer Spiralwinkel für schnelle Spanentfernung 22476 .2031 13/64" 5.159 3-15/16" 2-7/16"

4-Fasen-Anschliff Punkt

Empfohlen für Tiefe Bohrungen in Weiche Nichteisenmetalle (Aluminium, Messing und Bronze) 22486 .2055 #5 5.220 4" 2-1/2"

Empfehlung fuer den Einsatz auf der Drehmaschine 22496 .2130 #3 5.410 4" 2-1/2"

Schaft-Toleranz: h6 22501 .2165 5.500 102 64

22506 .2188 7/32" 5.558 4" 2-1/2"

22511 .2210 #2 5.613 4" 2-1/2"

22516 .2280 #1 5.791 4-1/8" 2-5/8"

Broca de submicrograno sólido carburo 22531 .2362 6.000 105 67

Ranuras anchas y abiertas y la hélice más alta evacúan las virutas con la máxima rapidez 22541 .2420 C 6.147 4-1/4" 2-3/4"

Punta de 4 caras

Recomendado para orificios profundos en material no ferroso blando (aluminio, latón, bronce) 22546 .2460 D 6.248 4-1/4" 2-3/4"

Recomendación para la aplicación en torno 22551 .2500 1/4" / E 6.350 4-1/4" 2-3/4"

Tolerancia del vástago: h6 22556 .2559 6.500 108 70

22561 .2570 F 6.528 4-3/8" 2-7/8"

22566 .2610 G 6.629 4-3/8" 2-7/8"

22571 .2656 17/64" 6.746 4-3/8" 2-7/8"

Forets carbure submicrograin 22576 .2660 H 6.756 4-3/8" 2-7/8"

Goujures tres larges egle d’helice eleve pour une evacuation plus rapide des copeaux 22581 .2720 I 6.909 4-3/8" 2-7/8"

Pointe avec 4 faces de depouille 22586 .2756 7.000 111 73

Recommander pour trous profonds dans matieres tenders non ferreuses

Outil de filature nécessaires pour une utilisation sur un processus de tournage 22596 .2810 K 7.137 4-7/16" 2-15/16"

Tolerance queue: h6 22606 .2900 L 7.366 4-7/16" 2-15/16"

22631 .3125 5/16" 7.938 4-11/16" 3-3/16"

Punte in sub-micro grana

Elica accentuata per una più veloce evacuazione del truciolo

Punto 4 facce

Fori profondi su materiali non ferrosi (alluminio, ottone, bronzo)

Utensili rotanti sono consigliate se usato su un tornio

Tolleranza gambo: h6

整体硬质合金钻头

开放式宽容屑槽和大螺旋角能快速清除切屑

4-小平面刀尖

推荐加工在软质有色金属(铝、黄铜和青铜)内钻深孔

不建议在车床,或工具必须纺纱

柄部公差: h6

90 www.garrtool.com ® ® ® † Metric equivalents are for reference only