Page 120 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 120

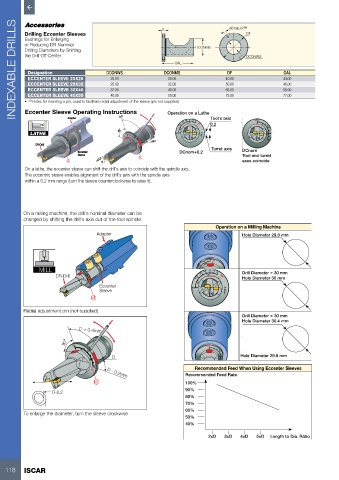

INDEXABLE DRILLS Drilling Eccenter Sleeves DCONWS 5 DCONMS DCONMS 40.00 DCONWS OAL

ø3 typ.x2 (1)

DF

Bushings for Enlarging

or Reducing DR Nominal

Drilling Diameters by Shifting

the Drill Off-Center

OAL

Designation

DF

25.00

44.00

ECCENTER SLEEVE 20X25

20.00

32.00

ECCENTER SLEEVE 25X32

46.00

25.00

50.00

65.00

55.00

40.00

ECCENTER SLEEVE 32X40

32.00

ECCENTER SLEEVE 40X50

40.00

75.00

77.00

50.00

• (1) Holes for inserting a pin, used to facilitate radial adjustment of the sleeve (pin not supplied)

Eccenter Sleeve Operating Instructions

Operation on a Lathe

0.0

Tool’s axis

Adapter

+12 +8 +4 +8 0 -4 -8 L M 0.2 +0.4 0 +0.2

LATHE 90 +0.4 +16 +4 0 +0.2 0

0 +0.2 X.001”

+0.2 L -0.2 M

DR-Drill +0.2 0

Turret axis

Eccenter DCnom+0.2 DCnom

-0.2 M

L

Sleeve L Tool and turret

L

L +0.2 0 axes coincide

On a lathe, the eccenter sleeve can shift the drill’s axis to coincide with the spindle axis.

The eccentric sleeve enables alignment of the drill’s axis with the spindle axis

within a 0.2 mm range (turn the sleeve counterclockwise to raise it).

On a milling machine, the drill’s nominal diameter can be

changed by shifting the drill’s axis out of the tool spindle.

Operation on a Milling Machine

Adapter Hole Diameter 29.8 mm

-0.2 M

0 +0.2 L

MILL +0.4 +0.2

0 +0.4 +8 +4 0 -4 -8 Drill Diameter = 30 mm

DR-Drill +0.2 +0.2 0 +12 +8 L M Hole Diameter 30 mm

Eccenter +4 0

L

-0.2 M

Sleeve +16 X.001”

M

Radial adjustment pin (not supplied)

Drill Diameter = 30 mm

Hole Diameter 30.4 mm

D + 0.4mm

90 +0.4 +0.4

0 +0.2 0 +0.2

D +0.2 0 Hole Diameter 29.8 mm

0

+0.2

L

Recommended Feed When Using Eccenter Sleeves

-0.2 M

-0.2 L M

Recommended Feed Rate

D - 0.2mm

M 100%

90%

D-0.2

80%

70%

D+0.4 60%

To enlarge the diameter, turn the sleeve clockwise

50%

40%

2xD 3xD 4xD 5xD Length to Dia. Ratio

118 ISCAR