Page 163 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 163

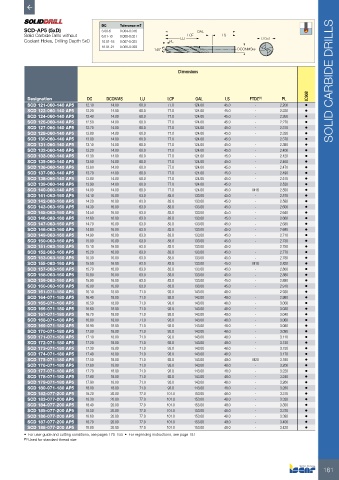

DC Tolerance m7

SCD-AP5 (5xD) 3.00-6 0.004-0.016 OAL

Solid Carbide Drills without 6.01-10 0.008-0.021 LCF LS

Coolant Holes, Drilling Depth 5xD 10.01-18 0.007-0.025 PL LU DCm7

18.01-21 0.008-0.029

140˚ DCONMSh6

Dimensions SOLID CARBIDE DRILLS

IC908

Designation DC DCONMS LU LCF OAL LS FTDZ (1) PL

SCD 121-060-140 AP5 12.10 14.00 60.0 77.0 124.00 45.0 - 2.200 •

SCD 122-060-140 AP5 12.20 14.00 60.0 77.0 124.00 45.0 - 2.220 •

SCD 124-060-140 AP5 12.40 14.00 60.0 77.0 124.00 45.0 - 2.260 •

SCD 125-060-140 AP5 12.50 14.00 60.0 77.0 124.00 45.0 - 2.270 •

SCD 127-060-140 AP5 12.70 14.00 60.0 77.0 124.00 45.0 - 2.310 •

SCD 128-060-140 AP5 12.80 14.00 60.0 77.0 124.00 45.0 - 2.330 •

SCD 130-060-140 AP5 13.00 14.00 60.0 77.0 124.00 45.0 - 2.370 •

SCD 131-060-140 AP5 13.10 14.00 60.0 77.0 124.00 45.0 - 2.380 •

SCD 132-060-140 AP5 13.20 14.00 60.0 77.0 124.00 45.0 - 2.400 •

SCD 133-060-140 AP5 13.30 14.00 60.0 77.0 124.00 45.0 - 2.420 •

SCD 135-060-140 AP5 13.50 14.00 60.0 77.0 124.00 45.0 - 2.460 •

SCD 136-060-140 AP5 13.60 14.00 60.0 77.0 124.00 45.0 - 2.470 •

SCD 137-060-140 AP5 13.70 14.00 60.0 77.0 124.00 45.0 - 2.490 •

SCD 138-060-140 AP5 13.80 14.00 60.0 77.0 124.00 45.0 - 2.510 •

SCD 139-060-140 AP5 13.90 14.00 60.0 77.0 124.00 45.0 - 2.530 •

SCD 140-060-140 AP5 14.00 14.00 60.0 77.0 124.00 45.0 M16 2.550 •

SCD 141-063-160 AP5 14.10 16.00 63.0 83.0 133.00 45.0 - 2.570 •

SCD 142-063-160 AP5 14.20 16.00 63.0 83.0 133.00 45.0 - 2.580 •

SCD 143-063-160 AP5 14.30 16.00 63.0 83.0 133.00 45.0 - 2.600 •

SCD 145-063-160 AP5 14.50 16.00 63.0 83.0 133.00 45.0 - 2.640 •

SCD 146-063-160 AP5 14.60 16.00 63.0 83.0 133.00 45.0 - 2.660 •

SCD 147-063-160 AP5 14.70 16.00 63.0 83.0 133.00 45.0 - 2.680 •

SCD 148-063-160 AP5 14.80 16.00 63.0 83.0 133.00 45.0 - 2.690 •

SCD 149-063-160 AP5 14.90 16.00 63.0 83.0 133.00 45.0 - 2.710 •

SCD 150-063-160 AP5 15.00 16.00 63.0 83.0 133.00 45.0 - 2.730 •

SCD 151-063-160 AP5 15.10 16.00 63.0 83.0 133.00 45.0 - 2.750 •

SCD 152-063-160 AP5 15.20 16.00 63.0 83.0 133.00 45.0 - 2.770 •

SCD 153-063-160 AP5 15.30 16.00 63.0 83.0 133.00 45.0 - 2.780 •

SCD 155-063-160 AP5 15.50 16.00 63.0 83.0 133.00 45.0 M18 2.820 •

SCD 157-063-160 AP5 15.70 16.00 63.0 83.0 133.00 45.0 - 2.860 •

SCD 158-063-160 AP5 15.80 16.00 63.0 83.0 133.00 45.0 - 2.880 •

SCD 159-063-160 AP5 15.90 16.00 63.0 83.0 133.00 45.0 - 2.890 •

SCD 160-063-160 AP5 16.00 16.00 63.0 83.0 133.00 45.0 - 2.910 •

SCD 161-071-180 AP5 16.10 18.00 71.0 93.0 143.00 48.0 - 2.930 •

SCD 164-071-180 AP5 16.40 18.00 71.0 93.0 143.00 48.0 - 2.980 •

SCD 165-071-180 AP5 16.50 18.00 71.0 93.0 143.00 48.0 - 3.000 •

SCD 166-071-180 AP5 16.60 18.00 71.0 93.0 143.00 48.0 - 3.020 •

SCD 167-071-180 AP5 16.70 18.00 71.0 93.0 143.00 48.0 - 3.040 •

SCD 168-071-180 AP5 16.80 18.00 71.0 93.0 143.00 48.0 - 3.060 •

SCD 169-071-180 AP5 16.90 18.00 71.0 93.0 143.00 48.0 - 3.080 •

SCD 170-071-180 AP5 17.00 18.00 71.0 93.0 143.00 48.0 - 3.090 •

SCD 171-071-180 AP5 17.10 18.00 71.0 93.0 143.00 48.0 - 3.110 •

SCD 172-071-180 AP5 17.20 18.00 71.0 93.0 143.00 48.0 - 3.130 •

SCD 173-071-180 AP5 17.30 18.00 71.0 93.0 143.00 48.0 - 3.150 •

SCD 174-071-180 AP5 17.40 18.00 71.0 93.0 143.00 48.0 - 3.170 •

SCD 175-071-180 AP5 17.50 18.00 71.0 93.0 143.00 48.0 M20 3.180 •

SCD 176-071-180 AP5 17.60 18.00 71.0 93.0 143.00 48.0 - 3.200 •

SCD 177-071-180 AP5 17.70 18.00 71.0 93.0 143.00 48.0 - 3.220 •

SCD 178-071-180 AP5 17.80 18.00 71.0 93.0 143.00 48.0 - 3.240 •

SCD 179-071-180 AP5 17.90 18.00 71.0 93.0 143.00 48.0 - 3.260 •

SCD 180-071-180 AP5 18.00 18.00 71.0 93.0 143.00 48.0 - 3.280 •

SCD 182-077-200 AP5 18.20 20.00 77.0 101.0 153.00 48.0 - 3.310 •

SCD 183-077-200 AP5 18.30 20.00 77.0 101.0 153.00 48.0 - 3.330 •

SCD 184-077-200 AP5 18.40 20.00 77.0 101.0 153.00 48.0 - 3.350 •

SCD 185-077-200 AP5 18.50 20.00 77.0 101.0 153.00 48.0 - 3.370 •

SCD 186-077-200 AP5 18.60 20.00 77.0 101.0 153.00 48.0 - 3.380 •

SCD 187-077-200 AP5 18.70 20.00 77.0 101.0 153.00 48.0 - 3.400 •

SCD 188-077-200 AP5 18.80 20.00 77.0 101.0 153.00 48.0 - 3.420 •

• For user guide and cutting conditions, see pages 175-184 • For regrinding instructions, see page 181

(1) Used for standard thread size

161