Page 113 - ISCAR(MILLINGCATALOG 38_2021)

P. 113

SELECTION GUIDE

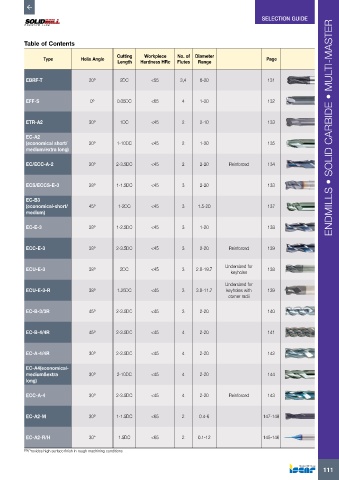

Table of Contents

Cutting Workpiece No. of Diameter

Type Helix Angle Page

Length Hardness HRc Flutes Range

EBRF-T 20º 2DC <55 3,4 6-20 131

EFF-S 0º 0.05DC <65 4 1-20 132

ETR-A2 30º 1DC <45 2 2-10 133 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

EC-A2

(economical short/ 30º 1-10DC <45 2 1-20 135

medium/extra long)

EC/ECC-A-2 30º 2-3.5DC <45 2 2-20 Reinforced 134

ECS/ECCS-E-3 38º 1-1.5DC <45 3 2-20 133

EC-B3

(economical-short/ 45º 1-2DC <45 3 1.5-20 137

medium)

EC-E-3 38º 1-2.5DC <45 3 1-20 138

ECC-E-3 38º 2-3.5DC <45 3 2-20 Reinforced 139

ECU-E-3 38º 2DC <45 3 2.8-19.7 Undersized for 138

keyholes

Undersized for

ECU-E-3-R 38º 1.25DC <45 3 3.8-11.7 keyholes with 139

corner radii

EC-B-3/3R 45º 2-3.5DC <45 3 2-20 140

EC-B-4/4R 45º 2-3.5DC <45 4 2-20 141

EC-A-4/4R 30º 2-3.5DC <45 4 2-20 142

EC-A4(economical-

medium&extra 30º 2-10DC <45 4 2-20 144

long)

ECC-A-4 30º 2-3.5DC <45 4 2-20 Reinforced 143

EC-A2-M 30º 1-1.5DC <65 2 0.4-6 147-148

EC-A2-R/H 30° 1.5DC <65 2 0.1-12 145-146

(1) Provides high surface finish in rough machining conditions

111