Page 115 - ISCAR(MILLINGCATALOG 38_2021)

P. 115

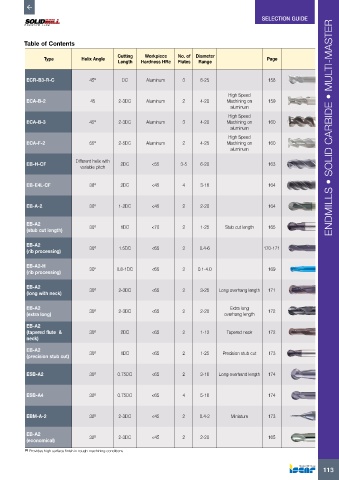

SELECTION GUIDE

Table of Contents

Cutting Workpiece No. of Diameter

Type Helix Angle Page

Length Hardness HRc Flutes Range

ECR-B3-R-C 45º DC Aluminum 3 8-25 158

High Speed

ECA-B-2 45 2-3DC Aluminum 2 4-20 Machining on 159

aluminum

High Speed

ECA-B-3 45º 2-3DC Aluminum 3 4-20 Machining on 160

aluminum ENDMILLS • SOLID CARBIDE • MULTI-MASTER

High Speed

ECA-F-2 55º 2-5DC Aluminum 2 4-25 Machining on 160

aluminum

Different helix with

EB-H-CF 2DC <55 3-5 6-20 163

variable pitch

EB-E4L-CF 38º 2DC <45 4 3-16 164

EB-A-2 30º 1-2DC <45 2 2-20 164

EB-A2 30º

(stub cut length) 1DC <70 2 1-25 Stub cut length 165

EB-A2 30º

(rib processing) 1.5DC <65 2 0.4-6 170-171

EB-A2-H

(rib processing) 30° 0.8-1DC <65 2 0.1-4.0 169

EB-A2 30º

(long with neck) 2-3DC <65 2 3-25 Long overhang length 171

EB-A2 Extra long

(extra long) 30º 2-3DC <65 2 2-20 overhang length 172

EB-A2

(tapered flute & 30º 2DC <65 2 1-12 Tapered neck 172

neck)

EB-A2 30º

(precision stub cut) 1DC <65 2 1-25 Precision stub cut 173

ESB-A2 30º 0.75DC <65 2 3-16 Long overhand length 174

ESB-A4 30º 0.75DC <65 4 5-16 174

EBM-A-2 30º 2-3DC <45 2 0.4-2 Miniature 173

EB-A2 30º 2-3DC <45 2 2-20 165

(economical)

(1) Provides high surface finish in rough machining conditions

113