Page 37 - ISCAR(MILLINGCATALOG 38_2021)

P. 37

Rd°

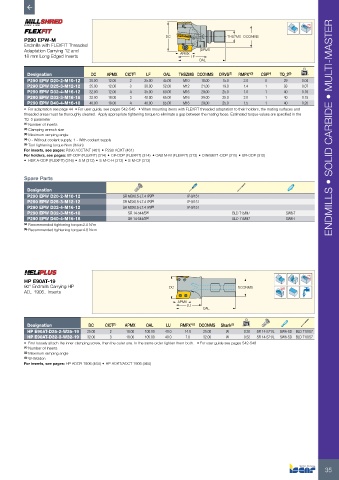

P290 EPW-M DC THSZMS DCONMS

Endmills with FLEXFIT Threaded

Adaptation Carrying 12 and APMX DRVS

18 mm Long Edged Inserts LF

OAL

Designation DC APMX CICT (1) LF OAL THSZMS DCONMS DRVS (2) RMPX° (3) CSP (4) TQ_3 (5) kg

P290 EPW D20-2-M10-12 20.00 12.00 2 25.00 45.00 M10 18.00 15.0 2.0 0 29 0.04

P290 EPW D25-3-M12-12 25.00 12.00 3 30.00 52.00 M12 21.00 19.0 1.4 1 33 0.07

P290 EPW D32-4-M16-12 32.00 12.00 4 35.00 60.00 M16 29.00 25.0 1.0 1 40 0.16

P290 EPW D32-3-M16-18 32.00 18.00 3 40.00 65.00 M16 29.00 25.0 2.0 1 40 0.15

P290 EPW D40-4-M16-18 40.00 18.00 4 40.00 65.00 M16 29.00 25.0 1.5 1 40 0.20

• For adaptation see page 44 • For user guide, see pages 542-548 • When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and

threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the

TQ_3 parameter

(1) Number of inserts

(2) Clamping wrench size ENDMILLS • SOLID CARBIDE • MULTI-MASTER

(3) Maximum ramping angle

(4) 0 - Without coolant supply, 1 - With coolant supply

(5) Tool tightening torque Nxm (lbfxin)

For inserts, see pages: P290 ACCT/KT (461) • P290 ACKT (461)

For holders, see pages: BT-ODP (FLEXFIT) (314) • C#-ODP (FLEXFIT) (314) • CAB M-M (FLEXFIT) (312) • DIN69871-ODP (315) • ER-ODP (315)

• HSK A-ODP (FLEXFIT) (316) • S M (312) • S M-C-H (312) • S M-CF (313)

Spare Parts

Designation

P290 EPW D20-2-M10-12 SR M3X0.5-L7.4 IP9 (b) IP-9/151

P290 EPW D25-3-M12-12 SR M3X0.5-L7.4 IP9 (b) IP-9/151

P290 EPW D32-4-M16-12 SR M3X0.5-L7.4 IP9 (b) IP-9/151

P290 EPW D32-3-M16-18 SR 14-544/S (a) BLD T15/M7 SW6-T

P290 EPW D40-4-M16-18 SR 14-544/S (a) BLD T15/M7 SW6-T

(a) Recommended tightening torque:2.0 N*m

(b) Recommended tightening torque:4.8 Nxm

Rd°

HP E90AT-19

90° Endmills Carrying HP DC DCONMS

AD.. 1906.. Inserts

APMX

LU

OAL

Designation DC CICT (1) APMX OAL LU RMPX° (2) DCONMS Shank (3) kg

HP E90AT-D25-2-W25-19 25.00 2 18.00 100.00 40.0 14.0 25.00 W 0.30 SR 14-571/L SW6-SD BLD T10/S7

HP E90AT-D32-3-W32-19 32.00 3 18.00 105.00 40.0 7.0 32.00 W 0.52 SR 14-571/L SW6-SD BLD T10/S7

• First loosely attach the inner clamping screw, then the outer one. In the same order tighten them both. • For user guide see pages 542-548

(1) Number of inserts

(2) Maximum ramping angle

(3) W-Weldon

For inserts, see pages: HP ADCR 1906 (464) • HP ADKT/ADCT 1906 (464)

35