Page 39 - ISCAR(MILLINGCATALOG 38_2021)

P. 39

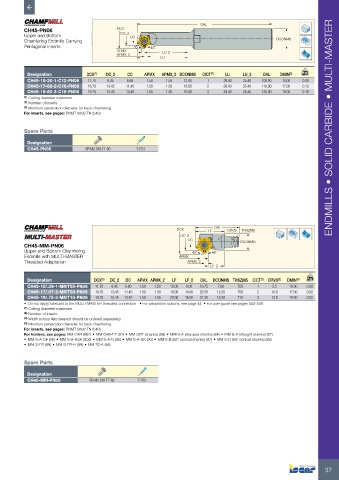

OAL

CH45-PN06 DCX

Upper and Bottom DC_2 DC

Chamfering Endmills Carrying DCONMS

Pentagonal Inserts 45˚ 45˚

APMX LU_2

APMX_2

LU

Designation DCX (1) DC_2 DC APMX APMX_2 DCONMS CICT (2) LU LU_2 OAL DMIN (3) kg

CH45-10-30-1-C12-PN06 11.70 8.45 6.60 1.50 1.50 12.00 1 29.40 25.40 100.00 10.00 0.00

CH45-17-60-2-C16-PN06 16.70 13.45 11.40 1.50 1.50 16.00 2 29.40 25.40 110.00 17.00 0.13

CH45-19-80-3-C16-PN06 18.70 15.45 13.40 1.50 1.50 16.00 3 29.40 25.40 130.00 19.00 0.16

(1) Cutting diameter maximum

(2) Number of inserts

(3) Minimum penetration diameter for back chamfering

For inserts, see pages: PNMT 0602-TN (540)

Spare Parts ENDMILLS • SOLID CARBIDE • MULTI-MASTER

Designation

CH45-PN06 SR M2.5X5-T7-60 T-7/51

DCX LF OAL DRVS THSZMS

DC_2 DC

CH45-MM-PN06 DCONMS

Upper and Bottom Chamfering 45˚ 45˚

Endmills with MULTI-MASTER APMX

Threaded Adaptation APMX_2

LF_2

Designation DCX (1) DC_2 DC APMX APMX_2 LF LF_2 OAL DCONMS THSZMS CICT (2) DRVS (3) DMIN (4) kg

CH45-10/.39-1-MMT05-PN06 11.70 8.45 6.60 1.50 1.50 13.00 9.00 19.75 7.60 T05 1 5.5 10.00 0.00

CH45-17/.67-2-MMT08-PN06 16.70 13.45 11.40 1.50 1.50 18.00 14.00 25.50 12.20 T08 2 10.0 17.00 0.02

CH45-19/.75-3-MMT10-PN06 18.70 15.45 13.40 1.50 1.50 20.00 16.00 31.30 15.30 T10 3 13.0 19.00 0.02

• Do not apply lubricant to the MULTI-MASTER threaded connection • For adaptation options, see page 44 • For user guide see pages 542-548

(1) Cutting diameter maximum

(2) Number of inserts

(3) Width across flats (wrench should be ordered separately)

(4) Minimum penetration diameter for back chamfering

For inserts, see pages: PNMT 0602-TN (540)

For holders, see pages: MM CAB (667) • MM CAB-T-T (91) • MM GRT (shanks) (86) • MM S-A (stepped shanks) (84) • MM S-A (straight shanks) (87)

• MM S-A-C# (86) • MM S-A-HSK (609) • MM S-A-N (85) • MM S-A-SK (90) • MM S-B (85° conical shanks) (87) • MM S-D (89° conical shanks) (88)

• MM S-ER (89) • MM S-ER-H (89) • MM TS-A (86)

Spare Parts

Designation

CH45-MM-PN06 SR M2.5X5-T7-60 T-7/51

37