Page 493 - ISCAR(MILLINGCATALOG 38_2021)

P. 493

S

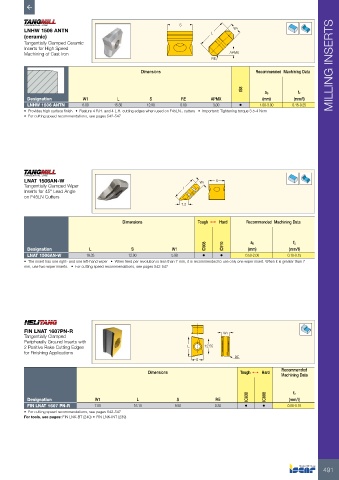

LNHW 1506 ANTN L W1

(ceramic)

Tangentially Clamped Ceramic

Inserts for High Speed

Machining of Cast Iron APMX

RE

Dimensions Recommended Machining Data MILLING INSERTS

IS8

ap fz

Designation W1 L S RE APMX (mm) (mm/t)

LNHW 1506 ANTN 6.00 15.30 12.90 0.80 3.00 • 1.00-3.00 0.15-0.25

• Provides high surface finish • Feature 4 R.H. and 4 L.H. cutting edges when used on F45LN.. cutters • Important: Tightening torque 3.5-4 Nxm

• For cutting speed recommendations, see pages 542-547

LNAT 1506AN-W W1 S

Tangentially Clamped Wiper L

Inserts for 45° Lead Angle

on F45LN Cutters

7.2

Dimensions Tough 1 Hard Recommended Machining Data

fz

ap

Designation L S W1 IC908 IC910 (mm) (mm/t)

LNAT 1506AN-W 19.33 12.90 5.98 • • 0.50-2.00 0.10-0.15

• The insert has one right- and one left-hand wiper • When feed per revolution is less than 7 mm, it is recommended to use only one wiper insert. When it is greater than 7

mm, use two wiper inserts. • For cutting speed recommendations, see pages 542-547

FIN LNAT 1607PN-R W1

Tangentially Clamped

Peripherally Ground Inserts with

2 Positive Rake Cutting Edges L 12.55

for Finishing Applications

RE

S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC808 fz

Designation W1 L S RE (mm/t)

FIN LNAT 1607 PN-R 7.00 16.10 9.50 0.30 • • 0.08-0.15

• For cutting speed recommendations, see pages 542-547

For tools, see pages: FIN LNK-BT (240) • FIN LNK-INT (239)

491