Page 494 - ISCAR(MILLINGCATALOG 38_2021)

P. 494

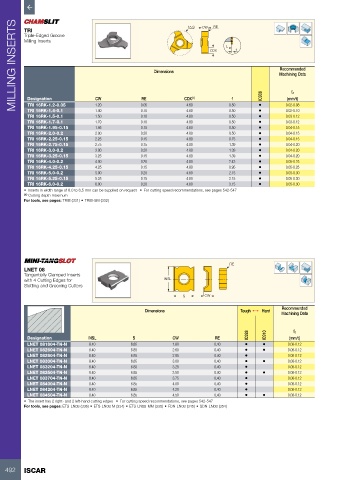

MILLING INSERTS TRI Dimensions 15.9 d CW CDX H L f D Recommended

RE

Triple-Edged Groove

Milling Inserts

Machining Data

fz

RE

Designation

f

(mm/t)

TRI 16RK-1.2-0.05

4.60

1.20

•

TRI 16RK-1.4-0.1

0.50

1.40

4.80

0.02-0.10

0.10

•

4.80

0.03-0.12

1.50

0.10

0.50

TRI 16RK-1.5-0.1 CW 0.05 CDX (1) 0.50 • IC908 0.02-0.08

TRI 16RK-1.7-0.1 1.70 0.10 4.80 0.50 • 0.03-0.12

TRI 16RK-1.95-0.15 1.95 0.15 4.80 0.50 • 0.04-0.15

TRI 16RK-2.0-0.2 2.00 0.20 4.80 0.50 • 0.04-0.15

TRI 16RK-2.25-0.15 2.25 0.15 4.80 0.75 • 0.04-0.15

TRI 16RK-2.75-0.15 2.75 0.15 4.80 1.39 • 0.04-0.20

TRI 16RK-3.0-0.2 3.00 0.20 4.80 1.39 • 0.04-0.20

TRI 16RK-3.25-0.15 3.25 0.15 4.80 1.39 • 0.04-0.20

TRI 16RK-4.0-0.2 4.00 0.20 4.80 2.43 • 0.05-0.25

TRI 16RK-4.25-0.15 4.25 0.15 4.80 0.95 • 0.05-0.25

TRI 16RK-5.0-0.2 5.00 0.20 4.80 2.15 • 0.05-0.30

TRI 16RK-5.25-0.15 5.25 0.15 4.80 2.15 • 0.05-0.30

TRI 16RK-6.0-0.2 6.00 0.20 4.80 3.15 • 0.05-0.30

• Inserts in width range of 6.0 to 6.5 mm can be supplied on request • For cutting speed recommendations, see pages 542-547

(1) Cutting depth maximum

For tools, see pages: TRIB (331) • TRIB-SM (332)

RE

LNET 08

Tangentially Clamped Inserts

with 4 Cutting Edges for INSL

Slotting and Grooving Cutters

S CW

Recommended

Dimensions Tough 1 Hard

Machining Data

IC928 IC910 fz

Designation INSL S CW RE (mm/t)

LNET 081804-TN-N 8.40 6.85 1.80 0.40 • • 0.08-0.12

LNET 082604-TN-N 8.40 6.85 2.60 0.40 • • 0.08-0.12

LNET 082804-TN-N 8.40 6.85 2.85 0.40 • 0.08-0.12

LNET 083004-TN-N 8.40 6.85 3.00 0.40 • • 0.08-0.12

LNET 083204-TN-N 8.40 6.85 3.25 0.40 • 0.08-0.12

LNET 083504-TN-N 8.40 6.85 3.50 0.40 • • 0.08-0.12

LNET 083704-TN-N 8.40 6.85 3.75 0.40 • 0.08-0.12

LNET 084004-TN-N 8.40 6.85 4.00 0.40 • 0.08-0.12

LNET 084204-TN-N 8.40 6.85 4.20 0.40 • 0.08-0.12

LNET 084504-TN-N 8.40 6.85 4.50 0.40 • • 0.08-0.12

• The insert has 2 right- and 2 left-hand cutting edges • For cutting speed recommendations, see pages 542-547

For tools, see pages: ETS-LN08 (336) • ETS-LN08-M (334) • ETS-LN08-MM (335) • FDN-LN08 (345) • SDN-LN08 (354)

492 ISCAR