Page 498 - ISCAR(MILLINGCATALOG 38_2021)

P. 498

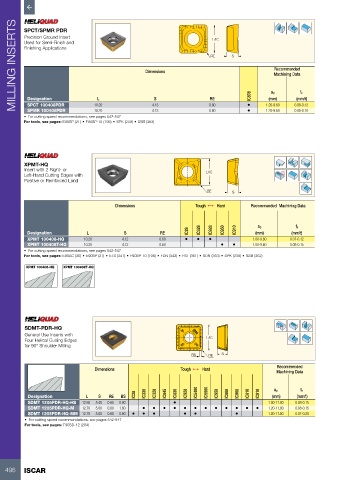

MILLING INSERTS SPCT/SPMR PDR Dimensions RE S Machining Data

Precision Ground Insert

L/IC

Used for Semi-Finish and

Finishing Applications

Recommended

fz

ap

RE

(mm/t)

L

S

Designation

(mm)

SPCT 100408PDR

10.20

•

4.13

SPMR 100408PDR

10.20

0.05-0.10

1.20-9.60

0.80

• For cutting speed recommendations, see pages 542-547 4.13 0.80 • IC808 1.20-9.60 0.08-0.12

For tools, see pages: E90SP (21) • F90SP-10 (198) • SPK (239) • SSB (362)

XPMT-HQ HQ

Insert with 2 Right- or L/IC Rd°

Left-Hand Cutting Edges with

Positive or Reinforced Land HQ

RE S

Dimensions Tough 1 Hard Recommended Machining Data

ap

fz

Designation L S RE IC28 IC328 IC928 IC950 IC910 (mm) (mm/t)

XPMT 100408-HQ 10.20 4.12 0.60 • • • 1.00-9.60 0.07-0.12

XPMT 100408T-HQ 10.20 4.12 0.60 • • 1.00-9.60 0.08-0.15

• For cutting speed recommendations, see pages 542-547

For tools, see pages: E90AC (36) • E90SP (21) • ETS (341) • F90SP-10 (198) • FDN (342) • FST (361) • SDN (353) • SPK (239) • SSB (362)

XPMT 100408-HQ XPMT 100408T-HQ

SDMT-PDR-HQ

General Use Inserts with L/IC

Four Helical Cutting Edges

for 90° Shoulder Milling

BS RE S

Dimensions Tough 1 Hard Recommended

Machining Data

fz

ap

Designation L S RE BS IC28 IC330 IC328 IC845 IC830 IC928 IC5400 IC5500 IC950 IC808 IC908 IC810 IC910 (mm) (mm/t)

SDMT 1205PDR-HQ-HS 12.60 5.40 0.60 0.80 • 1.00-11.80 0.08-0.15

SDMT 1205PDR-HQ-M 12.70 5.00 0.80 1.60 • • • • • • • • • • • • 1.20-11.80 0.08-0.15

SDMT 1205PDR-HQ-MM 12.75 5.00 0.80 0.80 • • • • • • 1.20-11.80 0.07-0.20

• For cutting speed recommendations, see pages 542-547

For tools, see pages: F90SD-12 (204)

496 ISCAR