Page 500 - ISCAR(MILLINGCATALOG 38_2021)

P. 500

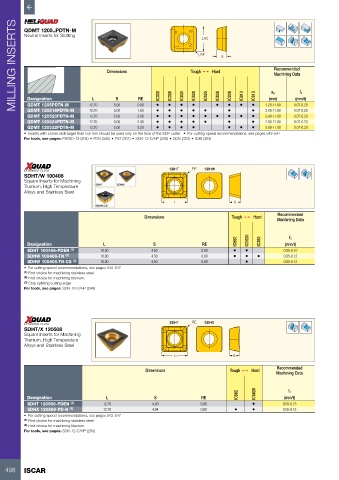

MILLING INSERTS QDMT 1205..PDTN-M Dimensions 1 4 2 Tough 1 Hard S Recommended

3

Neutral Inserts for Slotting

L/IC

RE

Machining Data

fz

ap

L

Designation

(mm/t)

(mm)

RE

S

QDMT 1205PDTN-M

•

•

•

•

•

•

5.00

QDMT 120516PDTN-M

12.70

0.07-0.20

2.00-11.80

1.60

•

•

•

•

•

•

•

•

•

5.00

12.70

2.00

QDMT 120520PDTN-M 12.70 5.00 0.80 • IC330 • IC328 • IC830 • IC928 • IC950 • IC808 • IC908 • IC810 • IC910 1.20-11.80 0.07-0.20

0.07-0.20

2.40-11.80

QDMT 120524PDTN-M 12.70 5.00 2.40 • • • • • • • 2.80-11.80 0.07-0.20

QDMT 120532PDTN-M 12.70 5.00 3.20 • • • • • • • 3.60-11.80 0.07-0.20

• Inserts with corner radii larger than 0.8 mm should be used only on the face of the SDK cutter • For cutting speed recommendations, see pages 542-547

For tools, see pages: F90SD-12 (204) • FDN (342) • FST (361) • SDK-12-C/HP (250) • SDN (353) • SSB (362)

SDHT RE SDHW

SDHT/W 100408

Square Inserts for Machining

Titanium, High Temperature

Alloys and Stainless Steel

L S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC882 IC5820 IC380 fz

Designation L S RE (mm/t)

SDHT 100408-PDEN (1) 10.00 4.50 0.80 • • 0.05-0.10

SDHW 100408-TN (2) 10.00 4.50 0.80 • • • 0.05-0.12

SDHW 100408-TN-CS (3) 10.00 4.50 0.80 • 0.05-0.12

• For cutting speed recommendations, see pages 542-547

(1) First choice for machining stainless steel

(2) First choice for machining titanium.

(3) Chip splitting cutting edge

For tools, see pages: SDK-10-C/HP (249)

SDHT RE SDHX

SDHT/X 120508

Square Inserts for Machining

Titanium, High Temperature

Alloys and Stainless Steel

L S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC882 IC5820 fz

Designation L S RE (mm/t)

SDHT 120508-PDEN (1) 12.70 4.90 0.80 • 0.05-0.15

SDHX 120508-PD-N (2) 12.70 4.94 0.80 • • 0.05-0.15

• For cutting speed recommendations, see pages 542-547

(1) First choice for machining stainless steel

(2) First choice for machining titanium

For tools, see pages: SDK-12-C/HP (250)

498 ISCAR