Page 502 - ISCAR(MILLINGCATALOG 38_2021)

P. 502

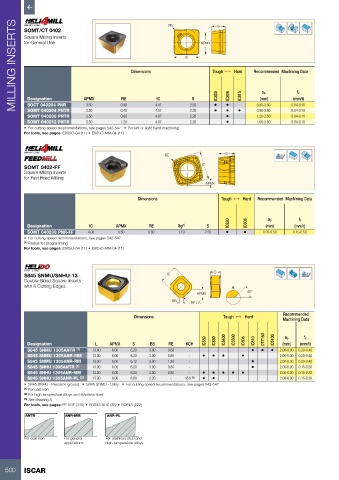

MILLING INSERTS SOMT/CT 0402 Dimensions RE IC APMX Tough 1 Hard Recommended Machining Data

S

Square Milling Inserts

for General Use

ap

fz

(mm/t)

S

Designation

(mm)

IC

RE

SOCT 040204 PNR

3.50

•

•

0.40

3.50

4.07

0.80-3.50

SOMT 040204 PNTR

2.20

0.04-0.10

•

0.80

SOMT 040208 PNTR APMX 0.40 4.07 2.20 • IC830 • IC808 • IC810 0.80-3.50 0.04-0.10

4.07

1.20-3.50

0.04-0.10

3.50

2.20

SOMT 040212 PNTR 3.50 1.20 4.07 2.20 • 1.60-3.50 0.04-0.10

• For cutting speed recommendations, see pages 542-547 • For left or right hand machining

For tools, see pages: E90SO-04 (11) • E90SO-MM-04 (11)

S

RE

SOMT 0402-FF IC

Square Milling Inserts

for Fast Feed Milling

APMX

Dimensions Tough 1 Hard Recommended Machining Data

IC830 IC808 ap fz

Designation IC APMX RE Rg (1) S (mm) (mm/t)

SOMT 040208 PNR-FF 4.08 0.50 0.80 1.10 2.20 • • 0.20-0.50 0.10-0.50

• For cutting speed recommendations, see pages 542-547

(1) Radius for programming

For tools, see pages: E90SO-04 (11) • E90SO-MM-04 (11)

S845 SNMU/SNHU-13 IC S

Double-Sided Square Inserts

with 8 Cutting Edges A

45°

APMX

BS RE / A

Dimensions Tough 1 Hard Recommended

Machining Data

IC330 IC830 IC5400 IC5500 IC808 IC810 DT7150 IC5100 ap fz

Designation L APMX S BS RE KCH (mm) (mm/t)

S845 SNMU 1305ANTR (1) 13.00 6.00 6.20 3.00 0.80 - • • • 2.00-6.00 0.20-0.40

S845 SNMU 1305ANR-MM 13.00 6.00 6.20 3.00 0.80 - • • • • 2.00-6.00 0.20-0.40

S845 SNMU 1305ANR-RM 13.00 6.00 6.12 3.00 1.20 - • 2.00-6.00 0.20-0.40

S845 SNHU 1305ANTR (1) 13.00 6.00 6.20 3.00 0.80 - • 2.00-6.00 0.15-0.30

S845 SNHU 1305ANR-MM 13.00 6.00 6.20 3.00 0.80 - • • • • • 2.00-6.00 0.15-0.30

S845 SNHU 1305ANR-PL (2) 13.00 6.00 6.00 2.20 - 45.0 (3) • • 2.00-6.00 0.15-0.30

• S845 SNHU - Precision ground • S845 SNMU - Utility • For cutting speed recommendations, see pages 542-547

(1) For cast iron

(2) For high temperature alloys and stainless steel

(3) See drawing A

For tools, see pages: FF SOF (310) • SOE45 8/16 (38) • SOF45 (222)

ANTR ANR-MM ANR-PL

For cast iron For general For stainless steel and

applications high temperature alloys

500 ISCAR