Page 540 - ISCAR(MILLINGCATALOG 38_2021)

P. 540

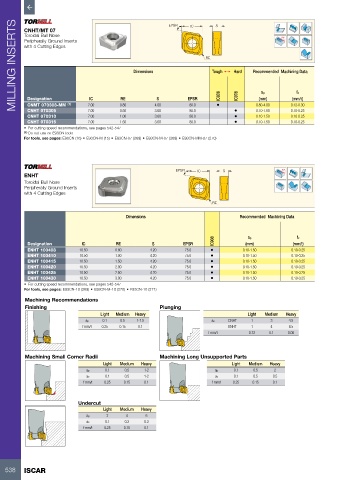

MILLING INSERTS CNHT/MT 07 Dimensions EPSR IC RE Tough 1 Hard Recommended Machining Data

S

Toroidal Bull Nose

Rd°

Peripherally Ground Inserts

with 4 Cutting Edges

fz

ap

(mm/t)

S

RE

IC

Designation

(mm)

CNMT 070308-MM

80.0

CNHT 070305

0.10-0.25

7.00

0.50

0.10-1.50

80.0

3.60

•

80.0

0.10-0.25

7.00

3.60

CNHT 070310 (1) 7.00 0.80 4.00 EPSR • IC808 • IC908 0.80-4.00 0.12-0.30

0.10-1.50

1.00

CNHT 070315 7.00 1.50 3.60 80.0 • 0.10-1.50 0.10-0.25

• For cutting speed recommendations, see pages 542-547

(1) Do not use on E93CN tools

For tools, see pages: E90CN (16) • E90CN-M (15) • E93CN-07 (269) • E93CN-M-07 (269) • E93CN-MM-07 (270)

EPSR Rd°

ENHT IC S

Toroidal Bull Nose

Peripherally Ground Inserts

with 4 Cutting Edges

RE

Dimensions Recommended Machining Data

IC908 ap fz

Designation IC RE S EPSR (mm) (mm/t)

ENHT 100408 10.50 0.80 4.20 75.0 • 0.10-1.50 0.10-0.25

ENHT 100410 10.50 1.00 4.20 75.0 • 0.10-1.50 0.10-0.25

ENHT 100415 10.50 1.50 4.20 75.0 • 0.10-1.50 0.10-0.25

ENHT 100420 10.50 2.00 4.20 75.0 • 0.10-1.50 0.10-0.25

ENHT 100425 10.50 2.50 4.20 75.0 • 0.10-1.50 0.10-0.25

ENHT 100430 10.50 3.00 4.20 75.0 • 0.10-1.50 0.10-0.25

• For cutting speed recommendations, see pages 542-547

For tools, see pages: E93CN-10 (269) • E93CN-M-10 (270) • F93CN-10 (271)

Machining Recommendations

Finishing Plunging

Light Medium Heavy Light Medium Heavy

ap 0.1 0.5 1-1.5 ae CNHT 1 3 4.5

f mm/t 0.25 0.15 0.1 ENHT 1 4 8.5

f mm/t 0.12 0.1 0.08

Machining Small Corner Radii Machining Long Unsupported Parts

Light Medium Heavy Light Medium Heavy

ap 0.1 0.5 1-2 ap 0.1 0.5 2

ae 0.1 0.5 1-2 ae 0.1 0.5 0.5

f mm/t 0.25 0.15 0.1 f mm/t 0.25 0.15 0.1

Undercut

Light Medium Heavy

ap 2 4 6

ae 0.1 0.2 0.3

f mm/t 0.25 0.15 0.1

538 ISCAR